2

SAMSUNG SV-A130 IK

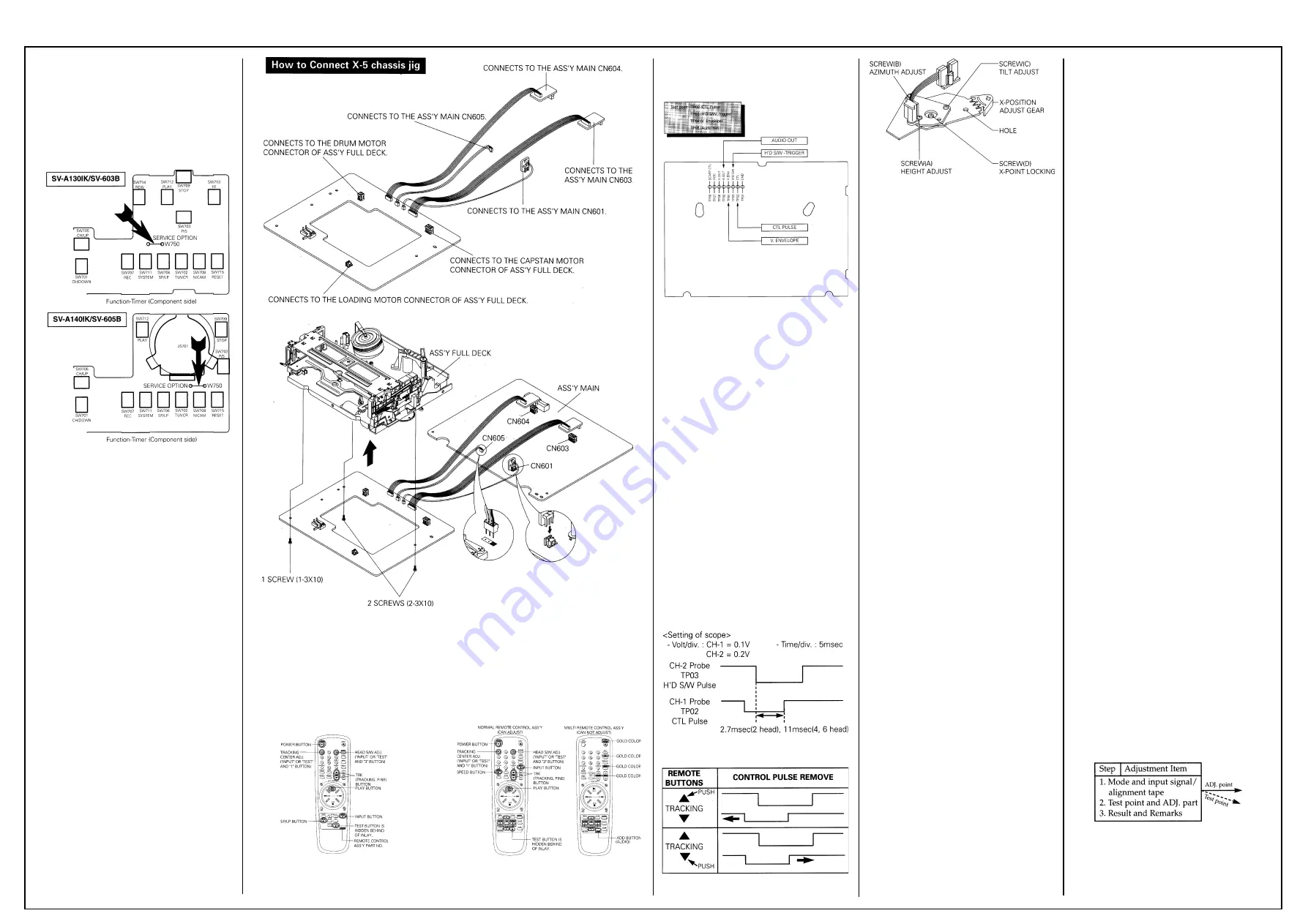

2-1-4 How to Connect X-5 chassis jig

1. Unplug the power cord from AC outlet.

2. Remove the deck ass’y from main PCB

3. To emulate the function of the sensors, place

a jumper or solder land (two point) at service

option (W750) on the function-timer PCB.

(see diagram below).

Note: After completing repairs, SW715 on the

function PCB in order to reset.

4. Insert wafers of drum motor, capstan motor

and loading motor on X-5 chassis jig into

each of the connectors of deck ass’y, and

then secure with three screws.

5. Solder the 3 leads of the jig cable to “CN605”

on the main PCB.

6. Apply power to the function PCB.

7. Insert a test tape into the housing ass’y.

8. Simultaneously touch the start and end

sensor LEDs on the PCB, so that the tape

loads automatically. After the tape is loaded,

all of the function buttons on the function PCB

can be used.

9. If the test tape is ejected while the jig is in

use, attempt to re-load the tape by simultane-

ously touching the start and end sensor

LEDs. If the tape still does not load, reset the

function PCB by pressing SW715.

Alignment & Adjustment

Note: After replacing the ass’y full deck, the

ass’y main, the cylinder ass’y and the micom

(IC601), the remote control ass’y can be used to

adjust the “X-point (tracking center) adjustment”

and “Head S/W point” adjustment.

5-1 Reference

5-1-1 The type of remote control ass’y

1. Remote control ass’y (AC93-10039Y/69099-

633-252) is specified as a service jig in the

service manual of X-5 /X-6(DX5-R/DX5-RC/

DX6-R/DX6-RC) chassis.

(See Fig. 5-1)

2. Normal remote control ass’y for X-7/X-8

(DX7-R/DX7-RC/DX8-R/DX8-RC) chassis.

(See Fig. 5-2)

5-1-2 How to identify between normal remote

Connecting X-5 Jig

control ass’y and multi remote control ass’y

for X-71X-8 chassis (See Fig. 5-2)

1. The color of some buttons related to TV

function are gold.

2. Audio button is added instead of the test

button hidden behind of inlay.

3. The positions of some buttons are different.

Fig. 5-1 Remote Control Assy Jig for X-5/X-6

Chassis (AC93-1 0039Y169099-633-252)

Fig. 5-2 Remote Control Assy for X-7/X-8

Chassis

Mechanical Adjustment

5-2-1 The number and position of test point

Fig. 5-3 The position of test point (Main PCB-

Component side)

5-2-2 X-Point(Tracking center) adjustment (See

the 2-2-1 (d) AC HEAD POSITION(X-POINT)

ADJUSTMENT

5-2-2 (a) IF THE REMOTE CONTROL ASSY IS

NOT AVAILABLE

1. Playback the colorbar alignment tape.

2. Connect CH-1 scope probe to “TP02” and

CH-2 scope probe to “TP03”. And then, trigger

head switching pulse.

3. Set tracking preset to llmsec (2head 2.7msec,

4, 6head: llmsec) using the “FINE (Tracking,

TRK)” button

▲

/

▼

of the other remote

control ass’y except the remote control ass’y

jig for X-5/X-6 chassis and the normal remote

control ass’y for X-7/X-8 chassis.

4. Connect CH-1 scope probe to “TP02” and the

CH-2 to “TP03” trigger on CH-1.

5. Insert the adjusting driver (+) into X-position

adjusting gear. Adjust the driver in either

direction for maximum envelope waveform.

Note: Since the adjusting gear unit may be

damaged, do not adjust by force when adjusting

the X-point using the adjusting driver (

±

). After

turn the X-point adjusting screw (D)

counterclockwise a little, perform the adjust-

ment. After adjustment is completed, tighten the

screw.

Fig. 5-4 Tracking preset adjustment

Fig. 5-5 Tracking preset adjustment

Fig. 5-6 Location of A/C Head adjustment screw

5-2-2 (b) IF THE REMOTE CONTROL ASSY

(AC93-10039Y/69099-633-252) IS AVAILABLE

Note: How to use the “TEST” button.

1. Disattach the inlay of remote control assy.

(See Fig. 5-1 and Fig. 5-2)

2. Press the “TEST” button with the pincers and

the precise driver as shown in Fig. 5-1 and 5-

2)

1. When using the “INPUT” button of remote

control ass’y;

1) Simultaneously press the “INPUT” button and

“1” button in PB mode. This will adjust the

tracking center automatically.

2) Set the tracking preset using the“FINE

(Tracking, TRK)” button of remote control.

3) After adjustment is completed, press the

“POWER” button to release.

2. When using the “TEST” button of remote

control ass’y;

1) Simultaneously press the “TEST” button and

“5” button in PB mode. This will adjust the

tracking center automatically.

2) Set the tracking preset using the “FINE

(Tracking, TRK) button of remote control.

3) After adjustment is completed, press the

“POWER” button to release.

5-2-2 (b) IF THE NORMAL REMOTE CONTROL

ASSY OF X-71X-8(DX7-RIDX7-RCl DX8-R/

DX8-RC) CHASSIS IS AVAILABLE

Note 1: Two kinds of remote control ass’y are

used for X-7/X-8(DX7-R/DX7-RC/DX8-R/DX8-

RC) chassis.

1. One is a normal remote control ass’y, the

other is a multi remote control ass’y

2. All adjustments are adjusted by normal

remote control ass’y only.

3. For the identification of normal remote control

ass’y and multi remote control ass’y.

Note 2: How to use the “TEST” button.

1. Disattach the inlay of remote control ass’y.

(See Fig. 5-1 and Fig. 5-2)

2. Press the “TEST” button with the pincers and

the precise driver as shown in Fig. 5-1 and 5-

2)

1. When using the “INPUT” button of remote

control ass’y;

1) Simultaneously press the “INPUT” button and

“1” button in PB mode. This will adjust the

tracking center automatically.

2) Set the tracking preset using the

“FINE(Tracking,

TRK)” button of remote control.

3) After adjustment is completed, press the

“POWER” button to release.

2.When using the “TEST” button of remote

control ass’y;

1) Simultaneously press the “TEST” button and

“5” button in PB mode. This will adjust the

tracking center automatically

2) Set the tracking preset using the “FINE

(Tracking, TRK) button of remote control.

3) After adjustment is completed, press the

“POWER” button to release.

Electrical Adjustment

5-3-1Head S/W Adjustment

Note: Only remote control ass’y can adjust.

5-3-1 (a) IF REMOTE CONTROL ASSY (AC93-1

0039Y/69099-633-252) IS AVAILABLE

1. When using the “INPUT” button of remote

control ass’y;

1) Insert an SP tape into the housing ass’y.

2) Press the “PLAY” button.

3) Press the “INPUT” button and “3” button

simultaneously.

4) This will adjust the head S/W point adjust-

ment automatically.

5) After the adjustment is completed, press

“POWER” button to release.

2. When using the “TEST” button of remote

control ass’y;

1) Insert an SP tape into the housing ass’y.

2) Press the “PLAY” button.

3) Press the “TEST” button and “SPILP” buttons

simultaneously.

4) This will adjust the head S/W point adjust-

ment automatically.

5) After adjustment is completed, press the

“POWER” button to release.

5-3-1 (b) IF NORMAL REMOTE CONTROL

ASSY FOR X-71X-8(DX7-RIDX7-RC/DX8-R/

DX8-RC) CHASSIS IS AVAILABLE

1. When using the “INPUT” button of remote

control ass’y;

1) Insert an SP tape into the housing ass’y.

2) Press the “PLAY” button.

3) Press the “INPUT” button and “3” buttons

simultaneously.

4) This will adjust the head S/W point adjust-

ment automatically.

5) After the adjustment is completed, press

“POWER” button to release.

2. When using the “TEST” button of remote

control ass’y;

1) Insert an SP tape into the housing ass’y.

2) Press the “PLAY” button.

3) Press the “TEST” button and “SPEED”

buttons simultaneously.

4) This will adjust the head S/W point adjust-

ment automatically.

5) After adjustment is completed, press the

“POWER” button to release.

5-3-2 RF AGC Adjustment

5-3-2 (a) ADJUSTMENT PROCEDURES

1. “F-F” (stop mode), RF signal.

2. TP07 and VR401.

3. Apply PAL color bar signal to the video input

terminal of the TV channel generator and set

Summary of Contents for SV-A130 IK

Page 4: ...4 SAMSUNG SV A130 IK Audio Video Diagram ...

Page 5: ...5 SAMSUNG SV A130 IK HiFi Diagram ...

Page 6: ...6 SAMSUNG SV A130 IK Nicam Diagram ...

Page 7: ...7 SAMSUNG SV A130 IK Power Supply Diagram ...

Page 8: ...8 SAMSUNG SV A130 IK Scart Diagram ...

Page 9: ...9 SAMSUNG SV A130 IK System Control Servo Diagram ...

Page 10: ...10 SAMSUNG SV A130 IK Timer Front PCB SV A130 SV 603 ...

Page 11: ...11 SAMSUNG SV A130 IK Timer Front PCB SV A140 SV 605 ...