4. Troubleshooting

M382xND/M382xDW/M402xND

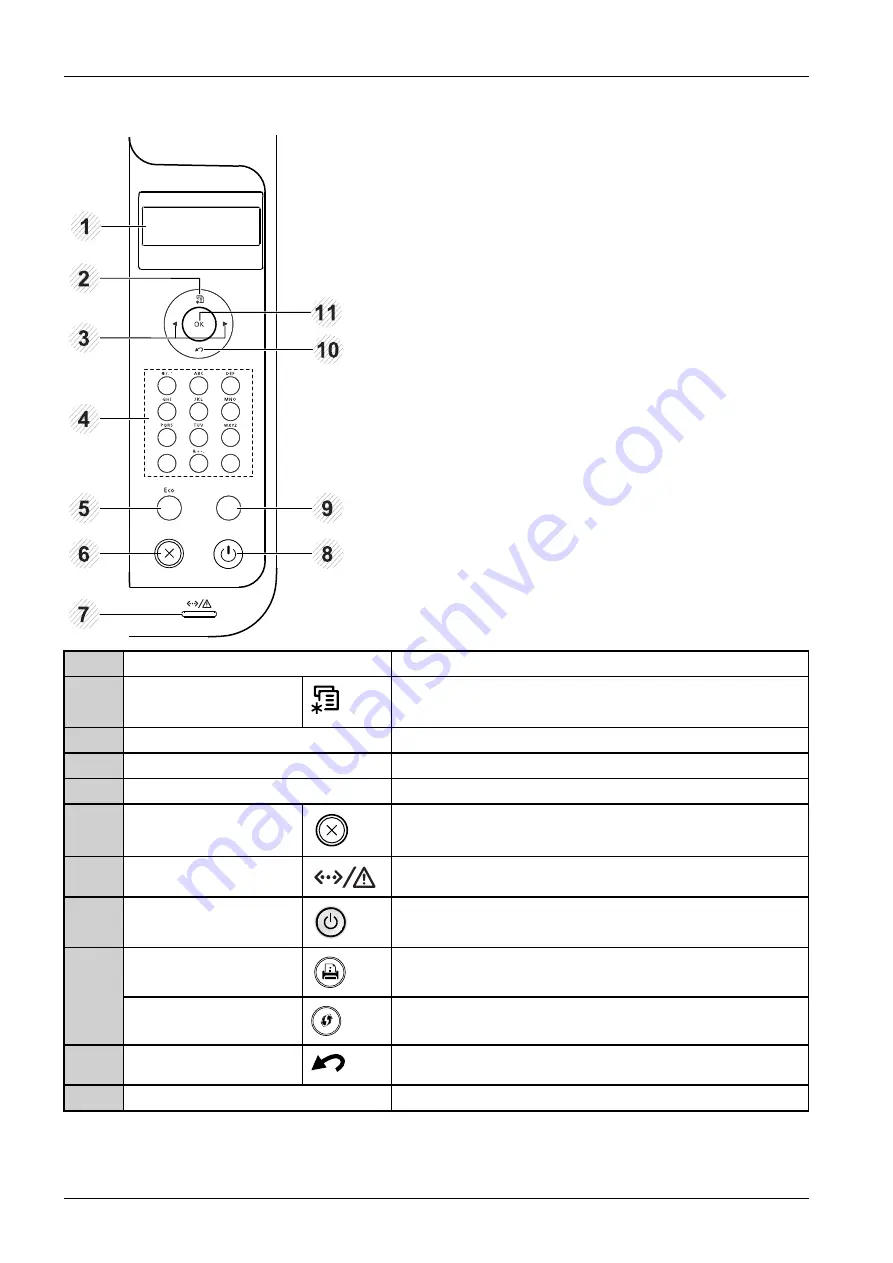

1

5

6

7

9

8

2

1

1

10

3

4

1

Display screen

Shows the current status and prompts during an operation.

2

Menu

Enters menu mode and scrolls through the available menus.

3

Arrow

Navigates available values by moving to the next or previous options.

4

Numeric keypad

Use the keypad to enter numbers and characters.

5

Eco

Enters eco mode to reduce toner consumption and paper usage.

6

Cancel

Stops current operation.

7

Status LED

Indicates the status of your machine.

8

Power

You can turn the power on and off with this button. Or wake up from

the power save mode.

Configuration sheet

Prints a demo page by pressing this button.

9

WPS

Configures the wireless network connection easily without a computer.

10

Back

Sends you back to the upper menu level.

11

OK

Confirms the selection on the screen.

4-2

Copyright© 1995-2016 SAMSUNG. All rights reserved.