5-3

Samsung Electronics

5-6 Output Power of Magnetron

The microwave heat distribution can be checked indirectly by measuring the water temperature risen at

certain positions in the oven :

1. Prepare five beakers made of 'Pyrex', having 100 milliliters capacity each.

2. Measure exactly 100milliliters off water load with a measuring cylinder and pour it into each beaker.

3. Measure the temperature of each water load.

(Readings shall be taken to the first place of decimals.)

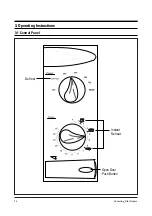

4. Put each beaker in place on the cooking tray as illustrated in figure

below and start heating.

5. After heating for 2 minutes, measure the temperatures of water in

each beaker.

6. Microwave heat distribution rate can be caicviated as follows :

Minimum

Temperature Rise

Heat Distribution =

X 100(%)

Maximum

Temperature Rise

The result should exceed 65%.

5-7 Microwave Heat Distribution - Heat Evenness

The output power of the magnetron can be measured by performing a water temperature rise test.

Equipment needed

*

Two 1-liter cylindrical borosilicate glass vessel (Outside diameter of 190mm)

* One glass thermometer with mercury column

NOTE

: Check line voltage under load. Low voltage will lower the magnetron output. Make all

temperature and time tests with accurate equipment.

1. Fill the one liter glass vessel with one liter of water.

2. Stir water in glass vessel with thermometer and record glass vessel's temperature as T1. (10

±

1˚C)

3. After moving the water into another glass vessel, place it on the center of the cooking tray. Set the oven

to high power and operate for 55 seconds exactly. (2 seconds included as a holding time of magnetron

oscillation)

4. When heating is finished, stir the water again with the thermometer and measure the temperature rise as T2.

5. Subtract R1 from T2. This will give you the water temperature rise. (

∆

T)

6. The output power is obtained by the following formula;

52 : Heating Time (sec)

* Output (W) = 100 x

∆

T

4.187 x 1000 x

∆

T

4.187 : Coefficient for Water

Output Power =

1000 : Water (cc)

52

∆

T : Temperature Rise (T2-T1)

7. Normal temperature rise for this model is 9˚C to 11˚C at 'HIGH'.

NOTE 1

: Variations or errors in the test procedure will cause a variance in the temperature rise.

Additional power test should be made if temperature rise is marginal.

NOTE 2

: Output power in watts is computed by multiplying the temperature rise (step E) by a power

factor of 91 in case of centigrade temperature.

Alignment and Adjustments

CAUTION

MICROWAVE RADIATION

PERSONNEL SHOULD NOT ALLOW EXPOSWRE TO MICROWAVE RADIATION FROM MICROWAVE GENERATOR OR

OTHER PARTS CONDUCTING MICROWAVE ENERGY.

D

D

D/4

D/4

D/4

D/4

Cooking Tray

Beaker