10

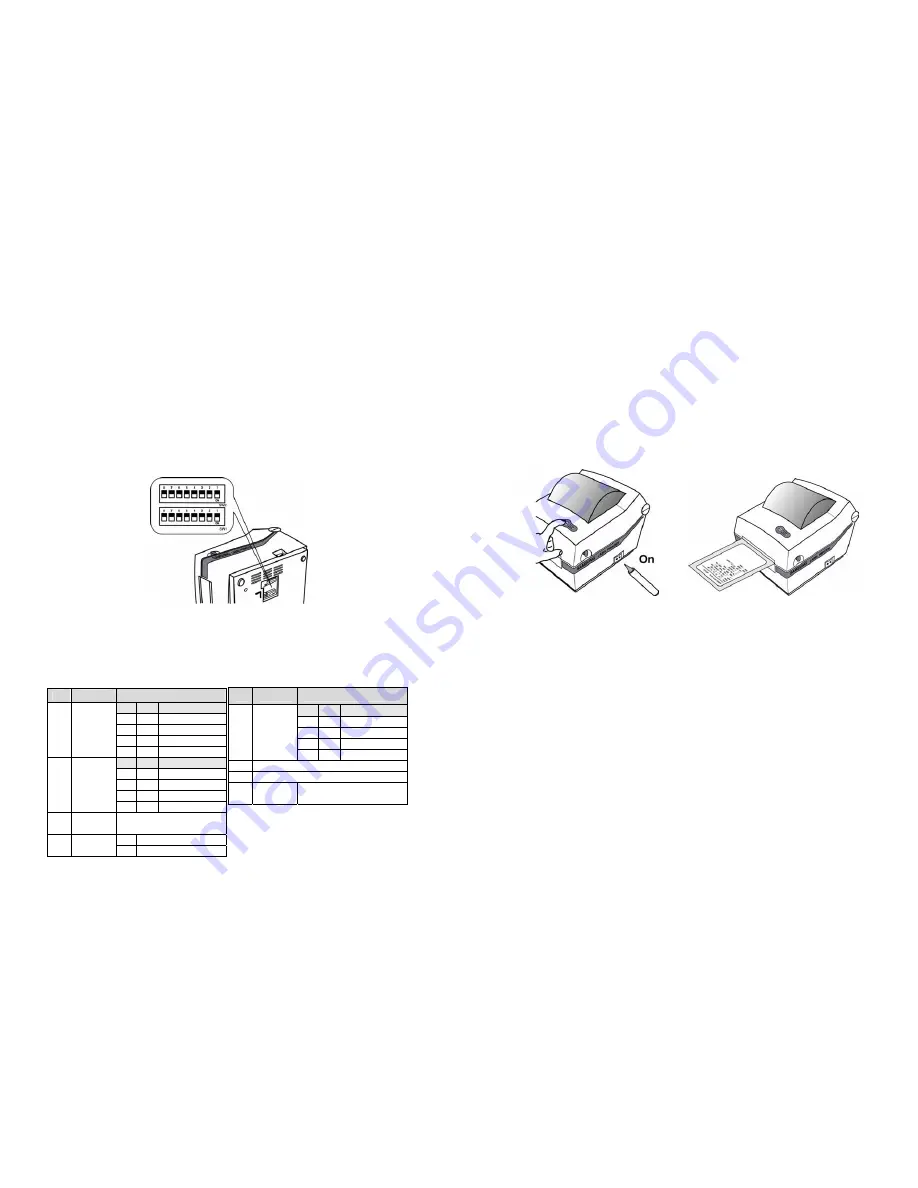

6. Setting The Dip Switches

6-1. Setting the Dip Switches

The Dip Switches are located on the bottom of the printer. The Dip Switches are used to

set the Printer to perform various functions. Follow these steps when changing Dip

Switches setting :

1.

Turn the printer power switch off.

2.

Remove the screw on the bottom of the printer and open the bracket.

3.

Flip the Dip Switches using tweezers or another narrow-ended tool. Switches are

off

when up and

on

when down in the Figure below.

4.

The new setting takes effect when you turn on the printer.

Note

: Always change Dip Switch settings only when the printer is turned off.

6-2. Functions of Dip Switches

6-2-1. Dip S/W 1 6-2-2. Dip S/W 2

NO Functions

Details

2

1

Speed

Off Off

2.5

ips

Off On

3.0

ips

On Off

4.0

ips

1,2

Speed

Selection

On On

5.0

ips

4

3

Density

Off Off

0(Low)

Off On

7

On Off

13

3,4

Density

Selection

On On

20(High)

5,6,

7

Developer

Mode

Default --- off

Off Move to Cutting Position

8

Position

Selection

On Move to top of next page

No

Functions

Details

2

1

Baud Rate

Off

Off

9,600 bps

Off

On

19,200 bps

On

Off

57,600 bps

1,2

Baud

Rate

On

On

115,200 bps

3 Reserved

4 Reserved

5~8

Developer

Mode

Default --- off

11

7. The Self Test

The self-test checks whether the printer has any problems. (You cannot perform this

procedure if using the printer’s label peel-off option) If the printer does not function

properly, contact your dealer. The self-test checks the following;

1.

Make sure that paper roll has been installed properly.

2.

Turn on the power while holding(2sec) down the FEED button. The self-test begins.

3.

The self-test prints the current printer status, which provides the control ROM version

and the DIP switch setting.

Cleaning Head

※

Paper dust on the heating elements may lower the printer quality. In this case, clean the

print head as follows :

Cautions

1. Turn Off the printer power before cleaning.

2. Note that the thermal head becomes very hot during normal operation,

creating the danger of burn injury. Be sure to wait for about 10 minutes

after turning printer power off before beginning the cleaning.

1. Open the printer cover.

2. Clean the thermal element (the area which is marked a thin black line) of the

thermal head with a cotton swab moistened with a alcohol solvent (ethanol,

methanol, or IPA).

3. After confirming that the alcohol solvent has been dried up completely,

close the cover-open.

Note 1. Never touch the thermal element with your hand,

then the thermal element can be damaged.

2. Don’t scratch the printer head.