- 11 -

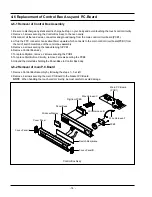

4. Disassembly and Reassembly

Remove the magnetron including the shield case,

permanent magnet, choke coils and capacitor (all

of which are contained in one assembly).

1. Remove the outer panel.

NOTE

: Before servicing, make sure to discharge

electric charge remaining on the high voltage

capacitors or wait for more than 5 min.

2. Remove the back cover.

3. Disconnect all lead wires from the magnetron.

4. Remove screws securing the duct-MGT and duct-fan.

5. Remove the nut-flanges securing the

magnetron by using a box wrench.

6. Take out the magnetron very carefully.

NOTE 1

: When removing the magnetron, make sure

that its antenna does not hit any adjacent

parts, or it may be damaged.

NOTE 2

: When replacing the magnetron, be sure to

remount the magnetron gasket in the cor-

rect position and make sure the gasket is in

good condition. (See page 19 for adjustment

instructions.)

Duct-MGT-L

Nut-Flange

Duct-Fan

Duct-MGT-R

Magnetron

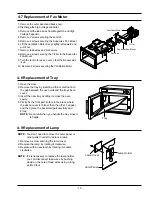

4-2 Replacement of High Voltage Transformer

1. Discharge the high voltage capacitor.

2. Disconnect all the leads.

3. Remove the mounting bolts securing the HVT.

4. Reconnect the leads correctly and firmly.

LVT

H. V. Trans

4 Mounting Bolts

4-1 Replacement of Magnetron