- 4 -

3. Operating Instructions

1

7

8

9

10

11

2

3

4

5

6

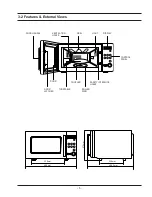

3-1 Control Panel

1. DISPLAY

2. AUTO REHEAT SELECTION

3. AUTO POWER DEFROST BUTTON

4. GRILL MODE SELECTION

5. COMBI MODE SELECTION

6. STOP/CANCEL BUTTON

7. CLOCK SETTING

8. CAFETERIA SELECTION

9. MICROWAVE/ POWER LEVEL

MODE SELECTION

10. AUTO CRUSTY COOK SELECTION

11. START BUTTON/ DIAL KNOB

(cook time, weight and serving size)