6. Troubleshooting

6-1 Electrical Maltunction

SYMPTOM

CAUSE

CORRECTIONS

Oven is dead.

Fuse is OK.

No display and no operation at all

.

1. Open or loose lead wire harness

2. Open thermal cutout (Magnetron)

3. Open low voltage transformer

4. Defective Ass'y PCB

Check fan motor when thermal

cutout is defective.

Check Ass'y PCB when LVT is

defective.

No display and no operation at all.

Fuse is blown.

1. Shorted lead wire harness

2. Defective primary latch switch

(NOTE 1)

3. Defective monitor switch (NOTE1)

4. Shorted HVCapacitor

5. Shorted HVTransformer (NOTE2)

Check adjustment of primary,

interlock monitor,

power relay, door sensing switch.

NOTE 1: All of these switches must be replaced at the same time.

(refer to adjustment instructions)

Check continuity of power relay contacts and if it has

continuity, replace power relay also.

NOTE 2: When HVTransformer is replaced, check diode and

magnetron also.

Oven does not accept

key input (Program)

1. Key input is not in-Sequence

2. Open or loose connection of

membrane key pad to Ass'y PCB

3. Shorted or open membrane panel

4. Defective Ass'y PCB

Refer to operation procedure.

Replace PCB main.

Timer starts countdown but no

microwave oscillation.

(No heat while oven lamp and fan

motor turn on.)

1. Off-alignment of latch switches

2. Open or loose connection of high

voltage circuit especially

magnetron filament circuit

NOTE: Large contact resistance will

bring lower magnetron

filament voltage and cause

magnetron to lower output

and/or intermittent oscillation.

3. Defective high voltage

components H.V.Transformer H.V.

Capacitor H.V.Diode, H.V.Fuse

Magnetron

4. Open or loose wiring of power

relay

5. Defective primary latch switch

6. Defective power relay or Ass'y PCB

Adjust door and latch switches.

Check high voltage component

according to

component test procedure and

replace if it is

defective.

Replace PCB main.

PRECAUTION

1. CHECK GROUNDING BEFORE CHECKING FOR TROUBLE.

2. BE CAREFUL OF THE HIGH VOLTAGE CIRCUIT.

3. DISCHARGE THE HIGH VOLTAGE CAPACITOR.

4. WHEN CHECKING THE CONTINUITY OF THE SWITCHES OR TRANSFORMER, DISCONNECT

ONE LEAD WIRE FROM THESE PARTS AND THEN CHECK CONTINUITY WITHOUT THE

POWER SOURCE ON. TO DO OTHERWISE MAY RESULT IN A FALSE READING OR DAMAGE

TO YOUR METER.

5. DO NOT TOUCH ANY PART OF THE CIRCUIT OR THE CONTROL CIRCUIT BOARD, SINCE

STATIC DISCHARGE MAY DAMAGE IT.

ALWAYS TOUCH GROUND WHILE WORKING ON IT TO DISCHARGE ANY STATIC CHARGE

BUILT UP.

Summary of Contents for CE2777R

Page 18: ...7 2 Main Parts List 0 0 ...

Page 19: ...7 3 Control Parts List S N A SERVICE NOT ASSEMBLY 0 0 1 ...

Page 20: ...7 4 Door Parts List 2 2 ...

Page 21: ...7 5 Standard Parts List 2 2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 3 0 2 ...

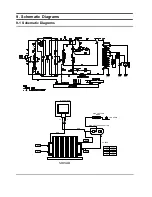

Page 22: ...8 P C B Diagrams 8 1 P C B Diagrams ...

Page 23: ...8 2 P C B Parts List 45 67 45 3 3 3 8 8 8 8 49 7 8 8 0 2 2 49 0 8 0 0 0 8 8 33 3 3 ...