4-3-5 Reassembly Test

Samsung Electronics

4-3

1. Disconnect the oven from the power source.

2. When 15A fuse blows out by the operation of interlock monitor switch failure, replace the primary

interlock switch, door sensing switch, monitor switch and power relay.

3. When the above three switches operate properly, check if any other part such as the control circuit board,

blower motor or high voltage transformer is defective.

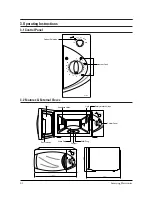

1. Take out the glass tray, guide roller and coupler from

cavity.

2. Turn the oven upside down to replace the drive motor.

3. Remove a screw securing the drive motor cover.

4. Disconnect all the lead wires from the drive motor.

5. Remove screws securing the drive motor to the cavity.

6. Remove the drive motor.

7. When replacing the drive motor, be sure to remount it

in the correct position.

8. Connect all the leads to the drive motor.

9. Screw the deive motor cover to the base plate with a

screw driver.

10. Remount the coupler in the correct position.

4-4 Replacement of Fuse

4-5 Replacement of Drive Motor

Disassembly and Reassembly

Screw

Drive Motor Cover

Base Plate

Drive Motor

After replacement of the defective component parts of the door, reassemble it and follow the instructions below for proper

installation and adjustment so as to prevent an excessive microwave leakage.

1. When mounting the door to the oven, be sure to adjust the door parallel to the bottom line of the oven

face plate by moving the upper hinge and lower hinge in the direction necessary for proper alignment.

2. Adjust so that the door has no play between the inner door surface and oven front surface. If the door

assembly is not mounted properly, microwave energy may leak from the space between the door and

oven.

3. Do the microwave leakage test.