- 9 -

5. Alignment and Adjustments

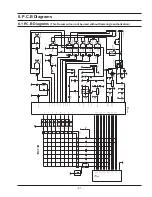

1. Remove connectors from the transformer terminals

and check continuity.

2. Normal resistance readings are as follows:

Secondary

Filament

Primary

Approx. 137Ω

Approx. 0Ω

Approx. 1.594Ω

(Room temperature = 20°C)

PRECAUTION

1. High voltage is present at the high voltage terminals during any cook cycle.

2. It is neither necessary nor advisable to attempt measurement of the high voltage.

3. Before touching any oven components or wiring, always unplug the oven from its power source and

discharge the high voltage capacitor.

1. Continuity checks can indicate only an open

fi lament or a shorted magnetron. To diagnose an

open fi lament or shorted magnetron :

2. Isolate the magnetron from the circuit by

disconnecting its leads.

3. A continuity check across the magnetron fi lament

terminals should indicate one ohm or less.

4. A continuity check between each fi lament terminal

and magnetron case should read open.

Primary

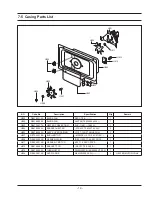

Terminals

Cooling Fins

5-3 Magnetron

5-1 High Voltage Transformer

5-2 Low Voltage Transformer

1. The low voltage transformer is located on the

Assy base plate.

2. Remove the low voltage transformer from the

Assy base plate and check continuity.

3. Normal resistor reading is shown in the table.

Terminals

Resistance

1~2(Input)

3~4(Output)

5~6(Output)

290

Ω

4.0

Ω

1.0

Ω