2

4.

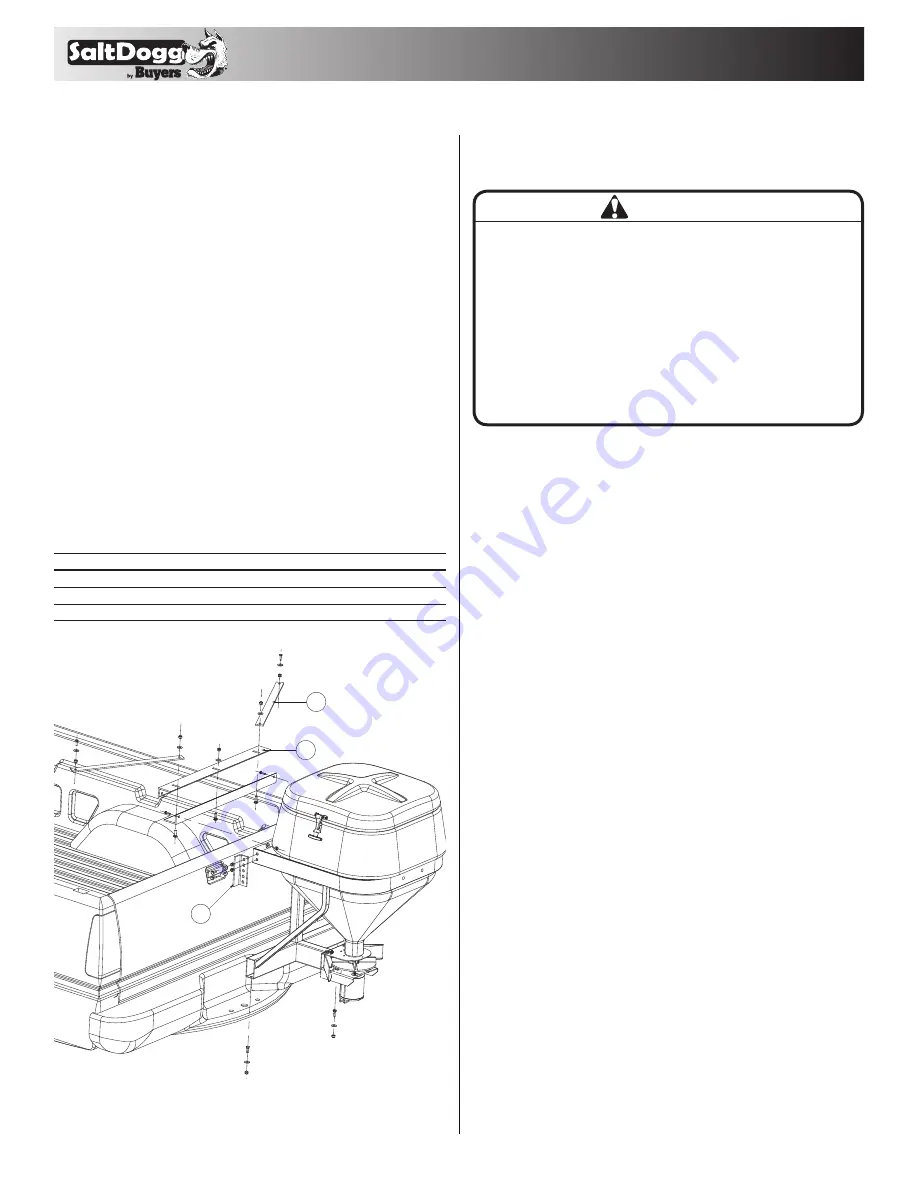

Position braces (23) on top of side rails. Using

holes in braces as guides mark and drill holes for 3/8"

screws.

5.

Attach braces to side rails using 3/8" screws, flat

washers and nuts.

6.

Center spreader assembly on top of rear bumper

and align with Angle (24).

7.

Attach Mounting Angles (22) to spreader frame.

8.

Make sure spreader frame is vertical. Using holes

in Angle (24), mark and drill holes for 3/8" screws in

Mounting Angle (22).

9.

Using holes in spreader frame as guides, mark and

drill holes for 3/8" screws in rear bumper.

10.

Assembly spreader to Angles (24) and rear bum-

per. Adjust position of Angles (24) to bring spreader

into vertical position. Tighten all screws at this

moment.

11.

Close tube with plastic caps provided.

WARNING

Do not drill holes into fuel tanks, fuel lines, through

electrical wiring, etc that may be damaged by drilling.

To insure good performance of your spreader, check the

condition of truck’s electrical system. Using digital volt-

meter, check alternator and battery voltage. With engine

running and head lights and heater fan ON good voltage

reading should fall between 13.0 and 15.3 volts. If volt-

age reading falls out of this range, check and adjust your

electric system.

Torque Chart

1/4-20

6.0

5/16-18

11.0

3/8-16

20.0

BOLT/NUT SIZE

TORQUE

(ft.-lbs.)

Electrical Installation

(fig. 2)

NOTE: Always disconnect battery before attempt-

ing to install electrical components on your

vehicle.

• Mount the controller in a convenient location in the

truck cab. It is recommended not to mount the con-

troller directly in front of heat vents.

• Route both wire harnesses into truck cab through

firewall (it maybe necessary to drill holes). Insulate

hole to avoid water leaks.

• Insure no wires are nicked or damaged during

installation.

• Connect the 4-pin connecter on the wire harness to

the control box.

• Connect the 2-pin connector on the power cable to

the control box.

• Lay out a path for the power cable to the bat-

tery, use quick ties to secure power cable.

DO NOT

CONNECT TO BATTERY AT THIS TIME!

• Lay out path for wire harness to the rear of the vehi-

cle. It is recommended to stay clear of the exhaust

system. Excess heat can damage the wire harnesses.

Use quick ties to secure harness to underbody.

• Connect the wire harness to the motor.

• Connect the power and ground cables directly to

the battery (Fig 2).

• Insure all functions of the controller are working

properly.

23

24

22

Fig. 1