FT TRUCK MT

12

Slope of Land

Spreading fertilizer up or down hill may cause the materials to be placed on a different area of

the spinner, thus changing the spread pattern. Spreaders with discharge chutes extending down

close to the spinners and having small openings through which fertilizer falls on the fans reduce

the variation due to slope.

On hillsides, the spreader will throw material further down hill than up. However, this just shifts

the spread pattern sideways and subsequent passes overlap properly. It is important to divide the

flow of the fertilizer equally between both distributors. This is accomplished with a center

divider, which extends from the flow divider to the gate.

Humidity

This causes fertilizer to adhere to flow divider and spinner blades. This build-up of material will

change the spread pattern. More of a problem is the fertilizer that adheres to the conveyor chain

and is carried forward under the spreader. This fertilizer falls off in a narrow streak and will

show up as a difference in crop growth. Any build-up of fertilizer on the spreader should be

cleaned off when it first begins to form.

Wind

When the wind is with or against the direction of travel it does not offset the spread pattern too

much. A crosswind will shift the entire pattern sideways. The final pattern remains reasonably

accurate for wind up to 15 mph. Crosswinds have more of an affect on lower density materials.

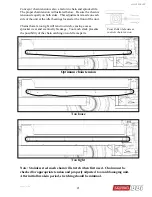

Diagram C

shows how wind can affect spread patterns.

Effect of Cross Wind

ADJUSTMENTS

Diagram C