Ignition of the burner

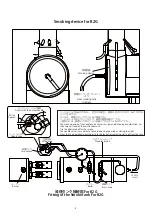

◆1.

(11) Light the alcohol in the pre-heating tray. Just before the alcohol is consumed, open the needle

valve slowly to about 15 degrees for burner ignition.*If not preheated sufficiently, the alcohol will

not be vaporized. In such cases, close the needle valve and repeat the process (9) above.

*The maximum opening of the needle valve is about 60 degrees

from full close. Adjust to the best position after 10 minutesʼ

operation.

*Usually itʼ s not necessary to open needles of both nozzles. When

you want greater steam for the engine, opening both needles is

required.

Steam up *Using the pressure gauge (option) is highly recommended.

(12) After the burner is ignited, it takes about 8-12 minutes to raise pressure sufficiently. When the

pressure gauge shows 1.0~1.5kgf/cm2, open the regulator quickly to full open position and return

to full close position to get rid of remaining air inside the boiler. Then pressure drops immediately

and rises gradually again.

(13) When the pressure gauge shows 1.0~2.0kgf/cm2, Steam up is completed and now you can

operate regulators to run the engine or use the whistle.

CAUTION

◆1.

Always keep fuel can, containers, and burnable material away from the burner. And keep a wet

towel nearby for an emergency.

◆2.

Excessive tightening may greatly shorten the life of packings (O-ring, gasket, or gland packing)

and even strip or break the threaded part of the needle valve, safety valves, and overflow plug.

◆3.

Always use fixed water and fuel levels for the boiler and burners.

◆4.

Do not fill up the boiler with hot water.

◆5.

If you restart the engine after stopping the burner forcibly by closing needle valve, there may be

fuel remaining in the burner. In such cases, the burner can be re-lit immediately while the tank is

still hot. But then DO NOT add any fuel.

Or after it gets cold, drain the remaining fuel from the burner (remove the safety valve [C] and

turn the burner upside down), and follow the process outlined in (3) to (13) above to restart.

◆6.

In case of engine racing, adjust the rpm using the needle valve and the regulator. Operating the

engine at high rpm can cause excessive wear or other damage.

◆7.

As long as you feed recommended quantities of water and fuel, the flame will extinguish in about

25minutes. The quantities are measured to ensure that there will be water left in the boiler when

the flame is extinguished. If excessive fuel is used, the boiler will become overheated after the

water has been depleted and the flame continues. This dry superheating can break some welded

sections and cause subsequent boiler leakage. In some cases, severe damage can result which

cannot be repaired.

- 3 -

Full open

approx. 60degs

Full close

0deg

Burner needle position

Summary of Contents for B2G

Page 6: ...6...