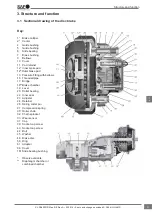

5.5 Inspecting the sealing elements

Guide bearing seal

Remove the brake pads (12) (see Chap. 6.1).

5.5.1 The guide bushings (4) and (5) must be

sealed with the bellows (9) and the cover (10)

or (68). Parts (9), (10) and (68) must not show any

cracks or damage (see Fig.).

Check for proper seating.

5.5.2 Remove the brake pads to inspect the inner

bellows (9) (observe Chap. 6.1).

If necessary, repair the brake calliper with a suitable

service kit (see Chap. 1.2 and Chap. 9).

Check the bellows on the pressure fittings (13)

5.5.3 Unscrew the pressure fittings (13) via the

adjuster (23) with the adapter (61) as far as is

necessary to be able to see the bellows clearly

(see Fig.).

Unscrew the pressure fittings (13) a minimum of

35 to maximum 40 mm or insert a new pad on

the outside and unscrew the pressure fittings as

far as the disc.

Caution!

5.5.3

The bellows on the pressure fittings (13)

must not exhibit any cracks or other damage

(see Fig.).

Check for proper seating.

Note: The ingress of dirt and moisture into the

brake will cause corrosion and impair the function

of the clamping mechanism and adjustment.

If necessary, replace the pressure fittings (13) with

bellows (see Chap. 7).

5.5.1 - Inspecting the calliper guide seal

5.5.3 - Unscrewing the pressure fittings min. 35 mm

to max. 40 mm

5.5.4 - Inspecting the bellows

Function and visual inspection

21

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND