21

8. The TurboTwister is designed to connect to a 1-1/2ӯ water supply line. Plumb the water supply from

the pool return line with a 1-1/2”Ø PVC pipe. Position the water supply “stub up” at the base of the

slide’s ladder, where the lower end of the 1-1/2”Ø Flex Hose (18) is located. The “stub up” should be

installed prior to mounting the slide to the deck. The “stub up” should be dark grey PVC to match the

slide’s plumbing assembly. Extend the water supply “stub up” to a height of 18” above the deck. It

can be cut to the desired length later, during the installation process.

9. Attach the “stub up” to the plumbing assembly installed in the slide as necessary.

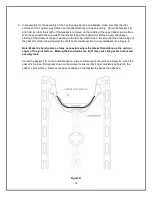

10. If a garden hose is going to be used to supply water to the slide, glue the Garden Hose Adapter (23)

and the 1-1/2ӯ x 3/4ӯ Reducer (22) together and then glue them into the bottom of the 1-1/2ӯ

Coupler (21), as shown in Figure V.

11. The TurboTwister can handle up to 25 gallons of water per minute (95L/min). The water flow can be

regulated with the 1-1/2ӯ Ball Valve (20).

Figure V