10

11

WARNING:

Do not allow familiarity with tools to make you care-

less. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear safety goggles or safety glasses with

side shields, a hard hat, and safety shoes when

operating tools. Failure to do so could result in

objects being thrown into your eyes, resulting in

possible serious injury.

WARNING:

Do not use any attachments or accessories not rec-

ommended by the manufacturer of this tool. The use

of attachments or accessories not recommended can

result in serious personal injury.

ASSEMBLY

FILLING TANK

n

Clean surface around fuel cap to prevent contami-

nation.

n

Loosen fuel cap slowly. Rest the cap on a clean

surface.

n

Carefully pour fuel into the tank. Avoid spillage.

n

Prior to replacing the fuel cap, clean and inspect the

gasket.

n

Immediately replace fuel cap and hand tighten. Wipe up

any fuel spillage.

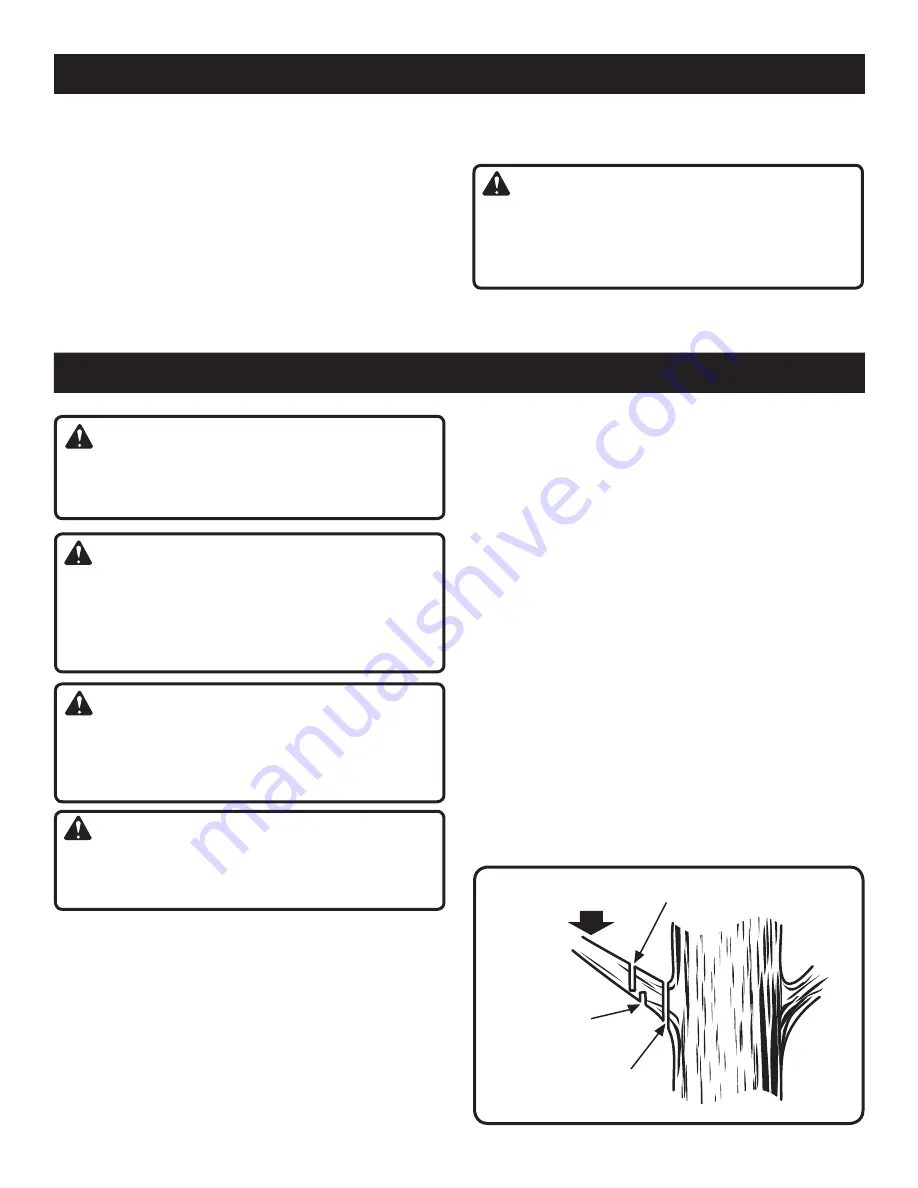

FINAL CUT

SECOND CUT

FIRST CUT

1/4 DIAMETER

LOAD

Fig. 5

OPERATION

WARNING:

To avoid kickback, binding of the saw bar, and possible

injury, never cut limbs that the pruner does not reach

when supported by the shoulder strap.

PREPARATION FOR CUTTING

See Figures 5 - 8.

n

Wear non-slip gloves for maximum grip and protection.

�

n

Maintain a proper grip on the unit whenever the engine is

running. Use your right hand to firmly grip the rear handle

while your left hand has a firm grip on the front handle.

�

n

Hold unit firmly with both hands. Always keep your left

hand on the front handle and your right hand on the rear

handle, so your body is to the left of the chain line. Never

use a left-handed (cross-handed) grip, or any stance that

places your body or arm across the chain line.

�

n

Never stand directly under the limb you are cutting.

�

n

Always wear shoulder strap for increased safety and to

support the pruner.

n

Be certain the knob is fully tightened before operating

equipment; check it periodically for tightness during use

to avoid serious injury.

BASIC CUTTING PROCEDURE

Follow the steps below to prevent damage to tree or shrub

bark. Do not use a back-and-forth sawing motion.

n

Accelerate the engine to full throttle just before entering

the cut by squeezing the throttle trigger. Keep the engine

at full throttle the entire time you are cutting.

n

Make a shallow first cut (1/4 of limb diameter) on the

underside of the limb close to the main limb or trunk.

n

Make a second cut from the top side of the limb outboard

from the first cut.

n

Make a final cut close to trunk.

�

NOTE:

For second and final cuts (from top of limb or branch),

hold front cutting guide against the limb being cut. This will

help steady the limb and make it easier to cut. Allow chain to

cut for you; exert only light downward pressure. If you force

the cut, damage to the bar, chain, or engine can result.

NOTE:

It is normal for smoke to be emitted from a new

engine after first use.

WARNING:

Always shut off engine before fueling. Never add fuel to

a machine with a running or hot engine. Move at least

30 ft. from refueling site before starting the engine. Do

not smoke!

Summary of Contents for RY52004

Page 23: ...23 NOTES...