13

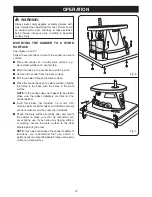

OPERATION

OPERATING THE SANDER

See Figures 8 and 9.

Follow these directions to operate the sander.

■

Insert the switch key.

■

Turn on the sander by lifting the switch.

■

Let the motor build to its full speed.

■

Feed the workpiece gradually against the sanding

sleeve from right to left.

WARNING:

Do not let the workpiece contact the sanding sleeve

before you turn on the sander and allow it to develop

full speed.

WARNING:

When you feed the workpiece from right to left, the

rotation of the sanding sleeve sands against the

workpiece. If you feed the workpiece in the opposite

direction, the rotation forces of the spinning sanding

sleeve tends to bounce the workpiece away from the

sanding sleeve. This action could cause you to lose

control of the workpiece.

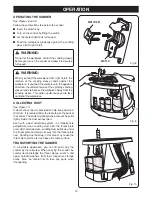

COLLECTING DUST

See Figure 10.

A dust exhaust port is provided to help keep dust to a

minimum. It is located under the table top on the back of

the sander. The end of a standard shop vacuum hose fits

tightly inside the dust exhaust port.

Even with a dust collection system, it is important to

periodically clean sanding dust from the throat plate

area. After extended use, sanding dust builds up under

the throat plate and forces its way into the throat plate

nest. Sanding dust build up in this area may cause the

throat plate surface to rise above the table surface.

TRANSPORTING THE SANDER

In a portable application, you can lift and carry the

sander by the table top. When carrying the sander, be

careful not to dislodge the throat plates, wrench, and

upper spindle washers from their respective storage

areas. Also, be careful not to lose any parts when

transporting.

Fig. 8

Fig. 9

Fig. 10

SWITCH KEY

SWITCH

Summary of Contents for OSS500

Page 15: ...15 NOTES...