2.3 The Linkage will provide the blade pivoting system to open and close the

blades through a rotation of 90 degrees. Refer to the ES catalogue for the

max operating parameters.

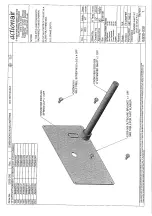

2.4 The ES damper can be operated by a manual quadrant or via a

∅

½

drive

spindle for motorisation by Actionair or others.

3.0

Installation Instructions.

3.1 Please ensure that the fixing framework and the ES damper flanges are

carefully matched when assembled together.

3.2 Ensure before installation that any wooden battens or packaging supplied

for transit strengthening purposes are removed. Failure to carry out this

procedure could result in permanent damage to the unit.

3.3 Before installation, the damper should be inspected to ensure that it has not

been damaged and is in good condition following transportation.

3.4 Please ensure that the damper frame and blades are free of any foreign

matter and that the assembly is not distorted in any manner and without

any dents and surface damage that could restrict blade movement.

3.5 Check that the dampers are operating correctly before carrying out

installation.

3.6 Flanged dampers when installed must be square and flat to avoid

additional torque being generated when opening and closing.

3.7 ES series dampers should not be installed with blades in the vertical

position.

3.8 Check that the dampers are operating correctly when dampers have been

installed.

4.0 Operation.

4.1 The ES series Air control damper is primarily designed for use in the

ductwork systems and can be used behind louver sets to control the

airflow. On the system being balanced during commissioning operations,

manual dampers can be locked in position by tightening the wing nut.

When dampers fitted with an actuator either by Actionair or by others you

should check the actuator operating instructions before attempting to rotate

the drive shaft when no power is available.

4.2 When actuators are fitted by others the extended drive shaft should be

fixed to the ‘F’ drive nearest centre of the damper. The supplier’s actuator

fitting recommendations should always be observed.