Owner’s Manual

Heat-Exchanger Unit Heaters

FR (Frost Resistant) & HP (High Pressure) Series Heaters

Warning

Please read all warnings and notices on page 2

Part No. 5347-8

Printed in Canada

ISO 9001:2000

CLASSIFICATION

All Ruffneck

TM

FR and HP heaters may be supplied with CSA or UL approved

explosion-proof motors for use in hazardous locations, Divisions 1 & 2, Class I, Groups

C & D and Class II, Groups E, F and G or TEFC (Totally Enclosed Fan Cooled) motors.

Ensure the motor meets the classification requirements.

This manual covers the installation, maintenance, repair

and parts for all FR and HP series heaters.

Ruffneck

TM

is a key brand of CCI Thermal Technologies Inc.

Copyright © 2007. All rights reserved

IMPORTANT NOTICES

WARNING

Read and adhere to the following.

Failure to do so may result in severe or fatal personal injury.

WARRANTY MAY BECOME VOID IF THESE WARNINGS ARE NOT FOLLOWED.

PLEASE SEE WARRANTY FOR FURTHER INFORMATION.

INSTALLATION

2

1. It is essential that any Ruffneck

TM

heater that will be used in a hazardous classified location be fitted with an electric motor that has

been approved for such service and that the fluid temperature is below the ignition temperature of the atmosphere.

2. Operate heater within the mounting guidelines set out in this manual.

3. For correct operation, the heater must be kept clean. Periodic checks to see if the unit is clean are required. If the unit is dirty, clean the

finned tubes, the fan, and the fan guard.

4. Never operate the heater with any or all louvers fully closed.

5. Do not operate in atmospheres which are corrosive to steel or aluminum.

6. Installation and wiring of the heater must adhere to all applicable codes.

7. For steam service use only single pass models (HP1 or FR1).

8. Heater is to be installed and serviced only by a person qualified and experienced with electrical and piping work.

9. Periodically inspect the cores for signs of corrosion and deformed headers. This must be done immediately after a suspected freeze up

or a steam system overpressure condition.

10. Cores that have deformed headers must be replaced as soon as possible.

11. When shutting down a Ruffneck

TM

steam heater, shut off the steam supply first then the heater fan.

WARNING

Disconnect heater from power supply before servicing or repairing heater. Lock the switch in the “OFF” (open)

position and/or tag the switch to prevent unexpected power application. This heater should only be serviced by

personnel with heating equipment experience. Some components of this heater are heavy and assistance will be

required to remove them.

DESCRIPTION

Two basic types of Ruffneck™ Heat Exchanger configurations are available from CCI Thermal Technologies Inc.:

FR (Frost Resistant) Series - for steam service only, up to 100 psi (690 kPa)

HP (High Pressure) Series - for steam and liquid service up to 400 psi (2,700 kPa) on select models

LOCATION OF HEATERS

The following guidelines have been established by CCI Thermal Technologies Inc. to ensure that you properly locate the heaters in

your building. These are only suggestions, and variations may be deemed necessary depending on application.

1.

When occupant comfort is the major objective, heaters should be positioned so that the airflow is directed to areas of

highest heat loss (i.e., doorways, windows and outside walls).

2.

For personnel comfort, a less turbulent and more even air distribution is required. To achieve this effect a larger quantity of

smaller unit heaters should be installed.

3.

When equipment protection is of utmost concern, heaters should be positioned so that the airflow is directed towards the

equipment.

4.

In very large areas, arrangement of heaters should be such that the air will exit from one heater and be projected towards

the inlet, or back, of another heater. A rotational airflow will result, with air circulation in the central area of the building.

Model

Motor HP

RPM

Throw in Feet

SOUND LEVEL dBA

MODEL

REAR

FRONT

3

5.

When arranging heaters, check the fan throws for the heaters being mounted (see table below).

Although it is not generally required that the fan throws reach the next heater, air circulation must be sufficient to prevent

cold spots from occuring.

6.

Do not install heaters such that airflow is blocked or impeded by equipment or walls.

7.

For warehouses or large workshops, it may be acceptable to use fewer, but larger, heaters mounted well above floor level.

it has to be recognized, however, that only the largest heaters have long fan throw distanced.

FAN THROWS FOR RUFFNECK

TM

HEAT-EXCHANGER UNIT AIR HEATERS

NOISE LEVELS

MEASURED SOUND LEVELS OF RUFFNECK

TM

HEAT-EXCHANGER AIR UNIT HEATERS

Where personnel inhabit a room or building for long periods of time, and local ambient noise levels are low,

the noise from the heaters has to be considered. Typically, the smaller the heater the lower the noise level will

be. The largest heaters that move large volumes of air are noticeably noisier than units handling low volumes

of air.

61

70

66

74

74

76

FR/HP - 12

FR/HP - 16

FR/HP - 20

FR/HP - 24

FR/HP - 30

FR/HP - 36

60

70

69

73

73

75

1/4

1/4

1/2

1/2

3/4

1 1/2

1725

1725

1725

1725

1140

1725

FR/HP - 12

FR/HP - 16

FR/HP - 20

FR/HP - 24

FR/HP - 30

FR/HP - 36

40

60

65

70

70

60

Note:

Sound levels were measured at a distance of 15 feet with louver blades horizontal and sound

meters on centreline of heater (i.e., in line with motor/fan shaft).

MOUNTING

Although Ruffneck™ Unit Heaters are designed to be installed in an upright and level position, they may be installed in

other positions. However, for steam service the inlet must be above the outlet and the bottom of the core must drain

toward the outlet. They are designed to be suspended from the top of the cabinet either with two or four (depending on

model) 5/8” NC bolts screwed into internally threaded holes provided in the cabinet top panel. It is essential that adequate

structural support be provided for installation.

Basic Mounting Kits (BMK), Hanging Mounting Kits (HMK), Swivel Hanging Mounting Kits (SHMK) or Wall Mounting Kits

(WMK) are available for Ruffneck™ heaters. If the strength of the structure is not adequate to support the units, a suitable

alternative such as the Ruffneck™ Pipe Mounting Kit (PMK) would be recommended to ensure safe and proper operation.

The HMK is the only suitable mounting kit for the 30” and 36” heater models.

Repair and Replacement Procedures

8

CORES

1. Remove the bottom cover which is attached with #10 screws and 1/4” bolts.

2. Take out the four 1/4” or 5/16” bolts on each side of the cabinet.

3. When removing the core assembly, it will usually be necessary to have assistance in order to handle it safely.

In some instances, dismounting the complete heater from support structure may be advisable to allow core

assembly removal at ground or bench level.

REMOVAL OF FAN, FAN GUARD OR MOTOR

(All models except FR/HP 36)

1. Remove the #10 screws that attach the fan guard to the cabinet.

2. Remove the motor, fan and fan guard together by removing the four 5/16” carriage bolts and nuts that attach

the motor to the motor bracket.

3. Before removing the fan from the motor shaft, measure the distance between the fan hub and the motor end

face. Make a note of this dimension to permit installation of the fan in the correct position at reassembly. The

fan guard must first be positioned over the motor shaft before the fan is installed on the shaft.

FR/HP 36

FAN GUARD

The fan guard consists of a removable upper panel and a frame bolted to the heater cabinet. For most service procedures

it is necessary only to remove the upper removable panel. In cases where the complete fan guard is to be removed,

assistance will be required due to its size and weight. To remove the complete fan guard:

1. Disconnect the wiring from the motor.

2. Remove the bolts fastening the fan guard to the cabinet and slide the fan guard past the motor.

V-BELT-SERVICE -- REMOVAL, INSTALLATION AND TENSIONING

1. Remove upper fan guard panel.

2. Slide motor mount up to relieve the tension to the v-belt and remove the v-belt.

3. Before installing a new v-belt, ensure that the sheaves are properly aligned. (See Drive Sheave Section)

4. Install the new v-belt and tension it by sliding the motor mount down until the v-belt will only move 10 to 16 mm

(3/8 to 5/8 in.) when 68N (15 lbs) of force are applied to the belt midway between the sheaves. Ensure that the

motor is level and then tighten the bolts fastening the motor mount to the drive frame.

5. Replace upper fan guard panel.

6. After a few days of operation the new v-belt will seat-in and may require adjustment.

WARNING

Disconnect heater from power supply before servicing or repairing heater. Lock the switch in the “OFF”

(open) position and/or tag the switch to prevent unexpected power application. This heater should only be

serviced by personnel with heating equipment experience. Some components of this heater are heavy

and assistance will be required to remove them.

9

FAN MOTOR - REMOVAL AND INSTALLATION

1. Remove bolts holding motor to the motor mount.

2. Remove the two piece fan guard assembly.

3. Lift the motor assembly off the motor mount.

4. Before removing the fan, measure and record the location of the fan hub on the motor shaft. If fan is difficult to

remove, use a gear puller on the fan hub.

5. To reassemble, position fan on motor shaft, and tighten set screws.

6. Place motor assembly onto motor mount, and fasten the fan guard to cabinet.

DRIVE SHEAVES - REMOVAL AND INSTALLATION

1. The sheaves on the fan motor and fan drive may be removed by removing the cap screws from the bushings.

2. Thread the cap screws into the threaded removal holes and progressively tighten the cap screws until the

sheave and bushing are loose and slide off the shaft.

3. To install; first slide the sheave with the bushing and cap screws in place onto the shaft. Align the sheaves.

4. Tighten the cap screws alternately until a torque of 10.8Nm (8ft.-lbs) is achieved. DO NOT over torque,

damage may result.

DRIVE FRAME - REMOVAL

1. Remove the complete fan guard assembly as described in the Fan Guard section.

2. Support the fan drives frame, then remove the bolts fastening it to the heater. Lower frame from the heater.

FAN SHAFT BEARINGS - REMOVAL AND INSTALLATION

The ball bearings used on the FR/HP-36 heaters are of the extended inner ring type, which use an eccentric

self-locking collar for a positive locking action of the shaft.

1. The fan shaft bearing may be serviced either on the heater by removing the upper fan guard panel or first

removing the whole drive frame from the heater.

2. Remove the v-belt and the drive sheave as described in the appropriate section.

3. Measure and record the distance from the end of the shaft to the bearing housing.

4. Loosen the set screws in the locking collars. Unlock the collars by placing a drift punch in the collar hole and hit

the punch opposite to the direction of shaft rotation.

5. Loosen and remove the bolts fastening the bearing to the bearing support and slide bearings off the shaft.

NOTE: It may be necessary to file the burr left by the bearings set screws on the shaft, in order to remove the

inner bearing.

6. To install new bearings; slide the bearings and locking collars onto the shaft with the locking collars facing each

other. Bolt bearings onto the bearing support. Position shaft using the measurement taken in Step 3.

7. Assemble locking collars to the bearing, turning them in the direction of shaft rotation and use a drift punch to

tighten the collar in place. Then tighten the set screws in the locking collars.

8. Reassemble the unit, ensuring the sheaves are aligned and the v-belt is tensioned as described in the

appropriate sections.

FAN - REMOVAL AND INSTALLATION

1. Remove the fan guard assembly as described in the Fan Guard Section.

2. Remove the drive frame as described in the Drive Frame Section.

3. Remove the set screws on the fan hub and remove the fan from the shaft. NOTE: if the shaft is corroded it may

be necessary to replace the shaft.

4. To reassemble, slide the shaft into the fan hub until the end of the hub. Ensure that the two flats on the shaft

align with the set screws in the fan hub. Then tighten the fan’s set screws.

10

ITEM

PART

FR, HP 12

FR, HP 16

FR, HP 20

FR, HP 24

FR, HP 30

NO.

DESCRIPTION

QTY NUMBER

QTY NUMBER

QTY NUMBER

QTY NUMBER

QTY NUMBER

1

FR1 CORE ASSEMBLY

1 2053

1 2054

1 2055

1 2056

1 2057

1

HP1 CORE ASSEMBLY

1 2051

1 1914

1 1986

1 2042

1 2043

1

HP3 CORE ASSEMBLY

1 2065

1 1936

1 1875

1 2045

1 2047

1

HP5 CORE ASSEMBLY

1 1983

1 1991

1 2046

1 2048

1

HP7 CORE ASSEMBLY

1 2190

1 2188

2

MOTOR BRACKET

1 1512

1 1217

1 1237

1 1219

1 1280

3

LOUVER BLADE KIT

1 4881

1 4882

1 4883

1 4884

1 4958

4

BOTTOM PANEL

1 7874

1 7868

1 7861

1 7960

1 8391

5

TOP PANEL

1 7875

1 7870

1 7865

1 7961

1 8395

6

RIGHT PANEL

1 7872

1 7866

1 9885

1 9057

1 8393

7

LEFT PANEL

1 7873

1 7867

1 9884

1 9058

1 8394

8

FAN SHROUD

1 7871

1 7869

1 7864

1 7962

1 8392

9

MOTOR

1

--

**

--

1

--

**

--

1

--

**

--

1

--

**

--

1

--

**

--

10

FAN BLADE

1 1513

1 1378

1 1382

1 1389

1 1386

11

FAN GUARD

2 5456

2 5457

2 5458

2 5459

2 5460

** Check motor name plate for voltage, phase, H.P., frame size, and service classification.

PARTS LIST

FR/HP 12, 16, 20, 24 and 30 models

1

8

15

16

7

10 11 14 17

12

5

13

9

2

6

4

3

11

PARTS LIST

FR/HP 36 models

ITEM

PART

FR, HP36

NO.

DESCRIPTION

QTY NUMBER

1

FR1 CORE ASSEMBLY

1 2058

1

HP1 CORE ASSEMBLY

1 2044

1

HP3 CORE ASSEMBLY

1 2049

1

HP5 CORE ASSEMBLY

1 2050

1

HP7 CORE ASSEMBLY

1 2189

2

MOTOR BRACKET

1 3426

3

LOUVER BLADE KIT

1 4959

4

BOTTOM COVER

1 1233

5

MOTOR

1

--

**

--

6

U-CLIPS

2 3444

7

FAN BLADE

1 1395

ITEM

PART

FR, HP36

NO.

DESCRIPTION

QTY NUMBER

8

FAN GUARD FRAME

1 3443

9

TAPER BUSHING, DRIVE

1

--

*

--

10

DRIVEN SHEAVE

1 1398

11

1” TAPER BUSHING, DRIVEN

1 1401

12

V-BELT

1 1402

13

DRIVE SHEAVE

1 1399

14

BEARING 1” PILLOW BLOCK

2 1396

15

FAN GUARD, UPPER PANEL

1 3455

16

FRAME, 36 FAN DRIVE

1 3424

17

SHAFT

1 1268

* Specify shaft diameter when ordering.

** Check motor name plate for voltage, phase, H.P., frame size, and service classification.

Maintenance Plan

5918 Roper Road

Edmonton, Alberta T6B 3E1

Canada

Phone: (780) 466-3178

Fax: (780) 468-5904

www.ccithermal.com

ISO 9001:2000

WARNING

Disconnect heater from power supply before servicing or repairing heater. Lock the switch in the “OFF”

(open) position and/or tag the switch to prevent unexpected power application. This heater should only be

serviced by personnel with heating equipment experience. Some components of this heater are heavy

and assistance will be required to remove them.

All terminal connections and wire installations should be inspected annually for damage, looseness, fraying defects, etc.

as applicable.

Keep the fins clear of any materials likely to plug or clog the fins. We suggest that cleaning of the cooling fins be

accomplished by use of an air nozzle.

The fan guard should be kept clear of any materials that may impede the air flow thereby reducing heater output capacity.

The unit’s fan should be inspected to ensure that the blades are not bent, dirty or running out of balance. If the blades are

dirty, they should be cleaned using water. The fan blades must not be allowed to operate in an unbalanced condition as

the fan blade(s) may fall from fatigue and possibly cause damage to the cooling fins of the heater cores.

If the output of the heater drops significantly, it is possible that the core tubes may have become partially blocked

internally. In such cases, the core should be flushed out with water or a suitable liquid. Flow should return to normal. but, in

extreme cases, reverse flow or flushing may be required (refer to Repair & Replacement Procedures for removal of core).

The bolts that attach the heater assembly and motor should be checked for tightness periodically. Please refer to Repair &

Replacement Procedures Section for further reference.

Warranty

CCI Thermal Technologies Inc. warrants all Ruffneck™ Unit Heaters against defects in materials and

workmanship; damage due to over-torquing of inlet/outlet connections; and for the FR Series units, damage

due to inadvertent freeze-up(s). CCI Thermal technologies Inc. will make good or replace any faulty equipment

within one year from date of purchase. Faulty equipment shall be returned to CCI Thermal Technologies Inc.

freight charges prepaid. This warranty shall be limited to the actual faulty equipment and under no

circumstances shall include or extend to installation costs or to consequential losses or damages.

PLEASE CALL BEFORE REPAIRING

It will save time and money. Failure to do so may be dangerous and may

void certain provisions of your warranty. For information regarding

installation, operation, repair, or purchase, please call our:

24 Hr. Hotline: 1-800-661-8529

(USA and Canada)

Please have model and serial numbers available before calling.

Phone: (780) 466-3178

Fax: (780) 468-5904

5

FIG.2

UNIT HEATER CONNECTION

FOR LOW-PRESSURE STEAM,

OPEN GRAVITY OR VACUUM

RETURN SYSTEM

NOTES:

1. For medium to high-pressure systems a bucket

or float trap must be used.

2. Do not use with fluids corrosive to steel.

3. Install using proper piping practices

4. In horizontal pipe runs, use eccentric reducers only.

5. Use a properly sized steam trap.

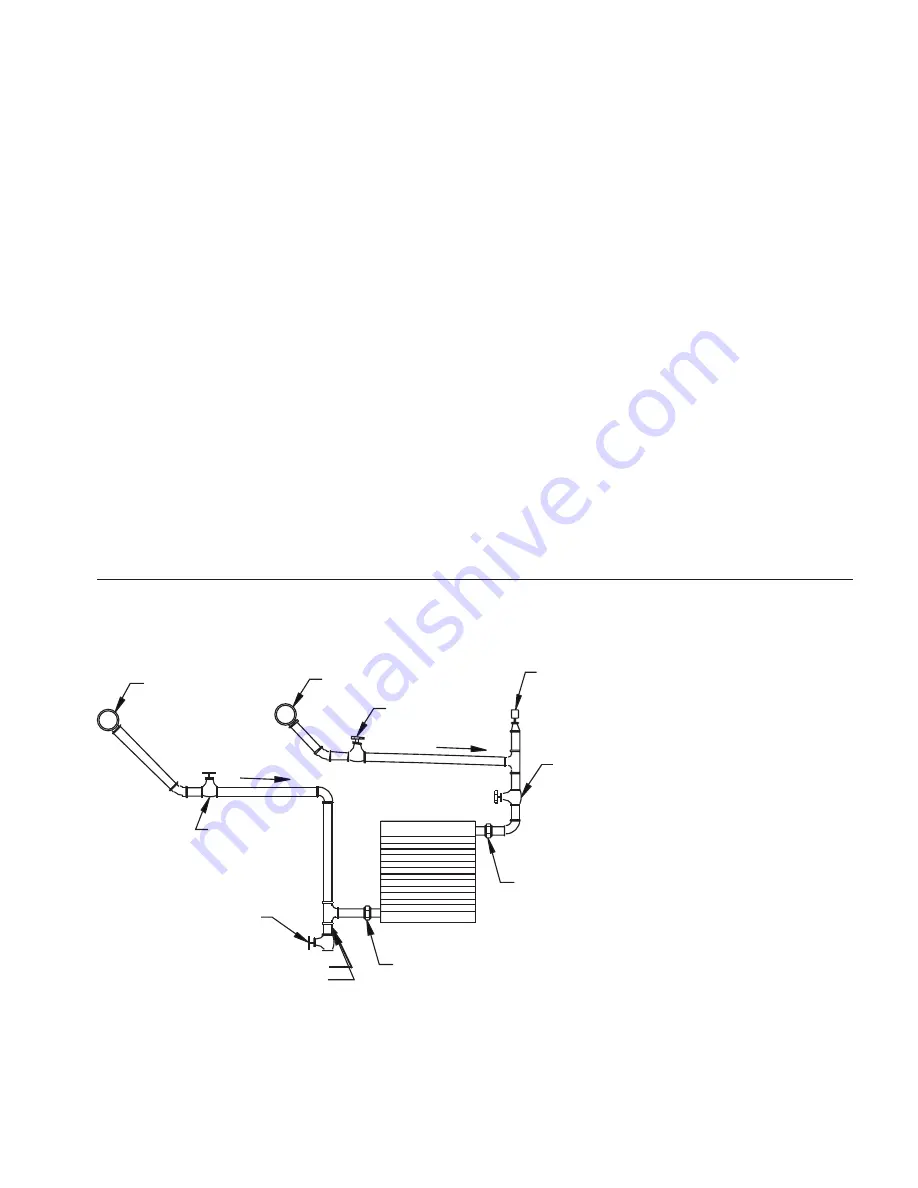

FIG.3

UNIT HEATER CONNECTIONS

TO OVERHEAD STEAM AND

RETURN MAINS

NOTES:

1. This piping arrangement is only for two-position-type

control. Modulating steam control may not provide sufficient

pressure to lift condensate to return main.

2. Do not use with fluids corrosive to steel.

3. Install using proper piping practices.

4. In horizontal pipe runs use eccentric reducers only.

5. Use a properly sized steam trap.

TAP INTO TOP OF MAIN

SHUT-OFF VALVE

UNION

PITCH DOWN

UNION

RETURN

MAIN

TAP INTO TOP OF MAIN

SHUT-OFF VALVE

PITCH DOWN

FULL SIZE DROP LEG

10.0 in. Min.

(254 mm)

SHUT-OFF VALVE

RETURN MAIN

PITCH

DOWN

LIFT NOT TO EXCEED 1 FT FOR

EACH POIND PRESSURE

DIFFERENCE BETWEEN STEAM

AND RETURN MAINS

THERMOSTATIC AIR

VENT OR PETCOCK.

(INSTALL IF TRAP DOES

NOT HAVE AIR VENT)

SHUT-OFF

VALVE

FLOAT AND

THERMOSTATIC

TRAP

STEAM

MAIN

UNION

UNION

UNION

UNION

SWING CHECK VALVE

STEAM TRAP WITH AIR VENT

STAINER AND DRAIN VALVE

6 in. (152mm) LONG

FULL SIZE

DIRT POCKET

STAINER

10 IN. Min.

(254 mm)

FULL SIZE DROP LEG

6 in. (152mm) LONG

FULL SIZE

DIRT POCKET

UNION

Electrical Wiring

7

Ruffneck

TM

fan-forced unit heaters and heat exchangers may be thermostatically controlled if required. Usually the flow of

heat transfer fluid is allowed to pass through the heat exchanger without interruption. The fan motor, in such cases, shuts

on and off by an electrical thermostat. Air flow through the heater is thus controlled. A small amount of heat will radiate

from the heat exchanger when the fan is inoperative but this is usually tolerable. Absolute control of heat output from the

heat exchanger would require that steam or flow of hot liquid to the heat exchanger be shut off. Such control of the heat

transfer medium is possible by thermostatic valve control, separately or in combination with thermostatic fan control.

Typically a manual shut-off valve is placed in the steam or liquid line for control purposes.

NOTES:

- Installation must comply with local electrical code.

- For internal wiring of control devices and starters, consult device manufacturer.

- The thermostat must have an electrical rating equal to or exceeding the HP, line voltage and current expected.

- For wiring of fan motor, refer to diagram on the motor name plate.

- Some motors may be equipped with external high-limit wires. These wires must be connected in series with the motor control circuit. (see

appropriate diagrams above)

SUPPLY VOLTAGE

208/230V

1PH

208/230 VOLT

CONTACTOR COIL

(NOT SUPPLIED)

EXTERNAL CONTROL PANEL

(NOT SUPPLIED)

230 VOLT

THERMOSTAT

THERMOSTATIC CONTROL FOR

208/230 VOLTS, 1 PHASE

THERMOSTATIC CONTROL FOR

115 VOLTS, 1 PHASE

THERMOSTATIC CONTROL FOR

208/230 VOLT, 3 PHASE MOTORS

C/W EXTERNAL HIGH-LIMIT WIRES

THERMOSTATIC CONTROL FOR

208/230 VOLTS, 3 PHASE

THERMOSTATIC CONTROL FOR

460/600 VOLTS, 3 PHASE

THERMOSTATIC CONTROL FOR

460/600 VOLT, 3 PHASE MOTORS

C/W EXTERNAL HIGH-LIMIT WIRES

FAN

MOTOR

FAN

MOTOR

FAN

MOTOR

FAN

MOTOR

SUPPLY VOLTAGE

115 VOLTS

1 PH

NEUTRAL

115 VOLT

THERMOSTAT

SUPPLY

VOLTAGE

208/230

VOLTS

3PH

SUPPLY VOLTAGE

208/230

VOLTS

3PH

208/230 VOLT

CONTACTOR COIL

3 POLE CONTACTOR RELAY

(NOT SUPPLIED)

EXTERNAL CONTROL PANEL

(NOT SUPPLIED)

3 POLE CONTACTOR RELAY

(NOT SUPPLIED)

SUPPLY

VOLTAGE

460/600

3PH

VOLTAGE

TRANSFORMER

(NOT SUPPLIED)

EXTERNAL CONTROL PANEL

(NOT SUPPLIED)

24 TO 230 VOLT

THERMOSTAT

230 VOLT

THERMOSTAT

208/230 VOLT

CONTACTOR COIL

MOTOR C/W EXTERNAL

HIGH-LIMIT WIRES

230 VOLT

THERMOSTAT

EXTERNAL CONTROL PANEL

(NOT SUPPLIED)

SUPPLY VOLTAGE

460/600

VOLTS

3PH

EXTERNAL CONTROL PANEL

(NOT SUPPLIED)

VOLTAGE

TRANSFORMER

(NOT SUPPLIED)

24 TO 230 VOLT

THERMOSTAT

3 POLE CONTACTOR RELAY

(NOT SUPPLIED)

MOTOR C/W EXTERNAL

HIGH-LIMIT WIRES

3 POLE CONTACTOR RELAY

(NOT SUPPLIED)

FAN

MOTOR

FAN

MOTOR

24 TO 230

VOLTS

24 TO 230

VOLTS

2" NPT FEMALE

CONNECTION

CONNECTION

5/8" UNC

K

D

G

H

L

F

B

I

A

E

C

J

CONNECTION

6

Physical Dimensions

DIM

FR/HP12

FR/HP 16

FR/HP 20

FR/HP 24

FR/HP 30

FR/HP 36

A

16 5/16 (415)

20 5/16 (516)

24 5/16 (618)

28 3/8 (720)

34 7/16 (874)

42 5/8 (1083)

B

16 3/8 (416)

20 5/16 (517)

24 5/16 (618)

28 1/4 (718)

34 5/16 (872)

42 5/8 (1083)

C

4 (102)

4 (102)

4 (102)

4 5/8 (118)

5 11/16 (145)

5 1/2 (140)

D

9 3/4 (248)

9 3/4 (248)

10 1/2 (267)

11 13/16 (300)

13 3/4 (350)

23 5/8 (600)

E

12 5/8 (320)

15 1/2 (394)

19 1/2 (495)

23 7/16 (596)

29 1/2 (750)

37 3/8 (950)

F

11 (280)

15 (381)

17 (432)

19 11/16 (500) 25 9/16 (650)

29 1/2 (750)

G

N/A

1 3/4 (44)

2 1/2 (63)

2 3/4 (70)

3 1/8 (80)

3 1/8 (80)

H

6 3/4 (172)

5 3/4 (147)

5 3/4 (146)

6 11/16 (170)

7 1/2 (190)

9 7/16 (240)

I

2 5/8 (68)

2 5/8 (68)

3 5/8 (93)

4 5/16 (109)

4 3/8 (111)

6 7/16 (163)

J

1 7/8 (48)

2 3/4 (70)

2 7/8 (73)

3 (76)

3 1/8 (80)

3 (76)

K*

(MAX)

21 1/4 (540)

21 1/4 (540)

22 7/16 (570)

23 5/8 (600)

25 3/16 (640)

34 5/8 (880)

L

(MAX)

1 5/8 (42)

1 5/8 (42)

1 5/8 (42)

1 5/8 (42)

1 7/8 (47)

1 3/4 (45)

Core weight

lbs (Kg)

27 (12)

38 (17)

48 (22)

91 (41)

121 (55)

175 (79)

Unit weight

lbs (Kg)

80 (36)

100 (45)

126 (57)

191 (87)

286 (130)

534 (242)

Shipping weight

lbs (Kg)

132 (60)

148 (67)

174 (79)

214 (97)

321 (146)

526 (239)

*May vary with motor used.

Note: The FR/HP12 has only

two mounting holes on

the top of the unit.

4

SHUT-OFF VALVE

PITCH DOWN

UNION

6 in. (152 mm) LONG

FULL SIZE

DIRT POCKET

RETURN

SUPPLY

PITCH DOWN

DRAIN VALVE

AUTOMATIC

AIR VENT

OR

PETCOCK.

SHUT-OFF VALVE

BALANCING

VALVE

UNION

Where heaters are installed in applications that are of a relocatable or transportable nature such as land or offshore drilling

rigs, an adequate mounting structure should be supplied to withstand all probable load conditions. Such load conditions

should recognize abuse situations such as truck off-loading impacts, etc. It is recommended that lock washers be used

beneath the bolt heads for these installations.

Heaters may be mounted at any reasonable height above floor level depending on the purpose of the heater. When

equipment is placed in a seldomly occupied building, the heaters may be placed at a low level. When heaters are required

to ensure personnel comfort, they should be mounted overhead. Typically, mounting heights range from 7 1/2 feet to 12

feet. All Ruffneck™ heaters have louvers installed that allow air flow to be directed from horizontal to 60 degrees or greater

downward deflection. Louvers should never be set to within less than 15 degrees of the closed position.

CLEARANCES FOR MAINTENANCE

It is important to provide adequate clearance around the heater for servicing. Allow enough space to permit easy fan or

motor replacement. Do not position the back of the fan motor against a surface, as air for the cooling fan will be blocked. It

is advisable to leave at least 2” clearance between the rear of the motor and the nearest obstruction. For easy removal of

the heat exchanger core assembly, it is important to leave clearance beneath the heater equal to the height of the heater

cabinet plus two inches.

PIPING APPLICATIONS

The following piping application and arrangements are only suggestions. Since it is impractical to cover all possible

applications, please refer to detailed piping references for more information.

Below are suggested piping arrangements.

FIG.1

UNIT HEATER

CONNECTIONS TO

OVERHEAD

FLUID MAINS

NOTES:

1. Do not use with fluids corrosive to steel

2. Install using proper piping practices.

CABINET MATERIAL

EPOXY POWDER COATED CARBON STEEL

A

HERESITE® PHENOLIC COATED CARBON

STEEL

B

STAINLESS STEEL

C

FRHP Heat-Exchanger Unit Heaters

Model Coding

HEATER SIZES AVAILABLE

MODEL & SIZE

HP1-12 THRU HP1-36

1 - Pass

HP1

HP3-12 THRU HP3-36

3 - Pass

HP3

HP5-16 THRU HP5-36

5 - Pass

HP5

HP7-24 THRU HP7-36

7 - Pass

HP7

FR1-12 THRU FR1-36

1 - Pass

FR1

MOTOR ENCLOSURE

1

TOTALLY ENCLOSED

2

X-PROOF, GR C, D, E , F & G

MOTOR ELECTRICAL

VOLTS

PHASE

HERTZ

A

115

1

60

B

208

1

60

C

208

3

60

D

230

1

60

E

230

3

60

F

460

1

60

G

460

3

60

H

575

3

60

I

220

1

50

J

380

3

50

K

440

3

50

Note: CCI units utilize a standard motor. Specifying any

other O.E.M. motor may result in longer lead times.

Heresite

®

coated exchangers and cabinets: contact

factory for quote.

Louvres and fan blades are also Heresite

®

coated.

Contact factory for shipping lead time.

Motor designed to be used at rated voltage with

tolerances of ±15%.

Motor may be marked 230 volts, but is suitable for 208

volt operation.

460 1 phase motors are only certified for groups D, F & G

Only available in 16” and larger units

Only available in 24” and larger units

TUBE MATERIAL

W

ALL

T

HIC

KNESS

R

OWS

FINNING

TUBING

FINS/

INCH

MATERIAL TYPE

A

.065"

3

10

AL

TW

5/8"

TW = Tension Wound

EX = Extruded

AL = Aluminum

SERIES

FAN

SIZE

CABINET

MATERIAL

EXCHANGER

COATINGS

CONNECTIONS

TUBE

MATERIAL

MOTOR

EXCHANGER COATINGS

HEAT RESISTANT ALUMINUM PAINT

1

HERESITE® PHENOLIC COATING

2

CONNECTIONS

2” NPT FEMALE

A

2” NPT MALE, SCH. 80

B

2” 300# RF FLANGE

C

FAN SIZE

12” DIA

12

16” DIA

16

20” DIA

20

24” DIA

24

30” DIA

30

36” DIA

36

HP1

12

A

1

A

1

1

A

12

13

NOTES