5

x

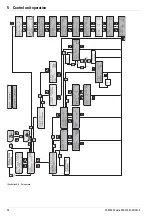

Control unit operation

38

FA ROTEX Solaris RPS3 25M - 03/2010

5.3.7 Correcting values for measurement points

If the measurement value of a sensor deviates from the true value, it can be compensated by means of a correcting value.

•

Find the correcting parameter via the menu path: "Choice 2/2" -> "System" -> "Correction values" (see Image 5-5) and

change the values according to Table 5-4.

Table 5-4 Correcting values

5.3.8 Burner inhibit contact

This contact controls an external heat generator in such a way that under favourable weather conditions, the storage tank is not

heated by the external source. For this purpose, the connecting cable BSKK (

16 41 10

), which is available as an accessory,

is required. If the Solaris system reaches an instantaneous output value (adjustable by a specialist via menu path: "Choice 1/2"

-> "Parameter choice" -> "Operating parameter "P min"") or if the storage tank is heated to a minimum temperature

(adjustable by a specialist via operating parameter "T

S

min" see Table 5-5) a contact disables e.g. the burner. The parameter

setting for the burner inhibit contact is described in Image 5-5.

It is possible to set a delay for the switching time of the burner inhibit contact by means of the "Time VBSK" parameter. If the

minimum storage tank temperature "T

S

min" is exceeded or if the preset minimum instantaneous output for burner stop "P min"

is exceeded, the burner inhibit contact only switches off after the set delay time has elapsed (see Image 5-6 for an example).

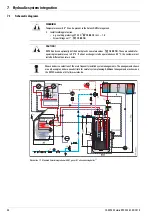

In the following example (Image 5-6) an imaginary course for the storage tank temperature is presented.

At time "t

1

", the minimum temperature for burner stop defined in operating parameter "T

S

min" is exceeded for the first time. As

the storage tank temperature "T

S

" falls below this value once more shortly afterwards, this does not result in activation of the

burner inhibit contact.

After the storage tank temperature "T

S

" is permanently exceeded at time "t

2

", this results in the activation of the burner inhibit

contact with the delay "VBSK" at time "t

3

". In a similar way, the burner inhibit contact is only deactivated at time "t

6

".

Name

Access level

Measurement &

adjusting range

Factory setting

Step width

Collector temperature correction

Specialist

-9 to +9

0 K

1 K

Return flow temperature correction

-9 to +9

0 K

1 K

Storage tank temperature correction

-9 to +9

0 K

1 K

Flow temperature correction

-9 to +9

0 K

1 K

Flow rate correction

-2 to +2

0 l/min

0.1 l/min

0

Not active

1

Active

t

Time

t

1

...t

6

Discrete points in time

BSK

Burner inhibit contact

TS

Storage tank temperature

TS min

Minimum temperature for burner stop

VBSK

Delay for burner inhibit contact

Illustration 5-6 Example: Function of the delay time when activating the burner inhibit contact