Section 02 717 ENGINE

Subsection 04 (BOTTOM END)

GENERAL

Engine has to be removed from watercraft to take

apart bottom end. Refer to appropriate

VEHICLE

SHOP MANUAL

.

Engine top end has to be disassembled to take

apart bottom end. Refer to TOP END section in

this manual.

NOTE:

Crankcase halves are factory matched and

therefore, are not interchangeable or available as

single halves.

DISASSEMBLY

PTO Flywheel

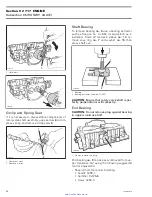

To remove PTO flywheel

no. 1

, the crankshaft

must be locked. Refer to MAGNETO SYSTEM

and follow the procedure to lock the magneto fly-

wheel.

PTO flywheel is loosen using the PTO flywheel

remover (P/N 295 000 001).

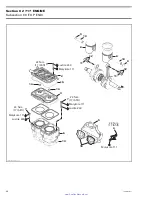

F01J0TA

Insert special tool in PTO flywheel splines.

F01D1AA

1

TYPICAL

1. PTO flywheel remover

Using a suitable wrench or socket with a break-

er bar, unscrew PTO flywheel COUNTERCLOCK-

WISE when facing it and hold extension handle

locking the magneto flywheel.

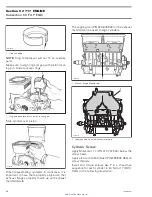

F00D0ZA

1

TYPICAL

1. Extension handle locking crankshaft

NOTE:

When splines of PTO flywheel are worn

out and special tool cannot be used, proceed with

the following alternate method.

Use a pipe wrench and install it on PTO flywheel

as illustrated.

F00D10A

1

TYPICAL

1. Extension handle locking crankshaft

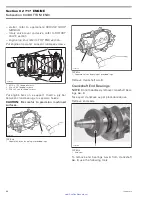

Crankshaft End Seals

If crankshaft end seals

no. 5

have to be re-

placed, bottom end must be opened. Refer to

CRANKCASE and CRANKSHAFT END BEARINGS

below.

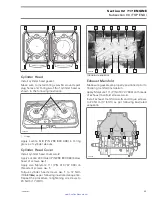

Crankcase

Before opening crankcase

no. 2

, remove the fol-

lowing parts:

– engine supports

– magneto flywheel and housing, refer to MAG-

NETO SYSTEM section

smr2005-078

39

www.SeaDooManuals.net