10

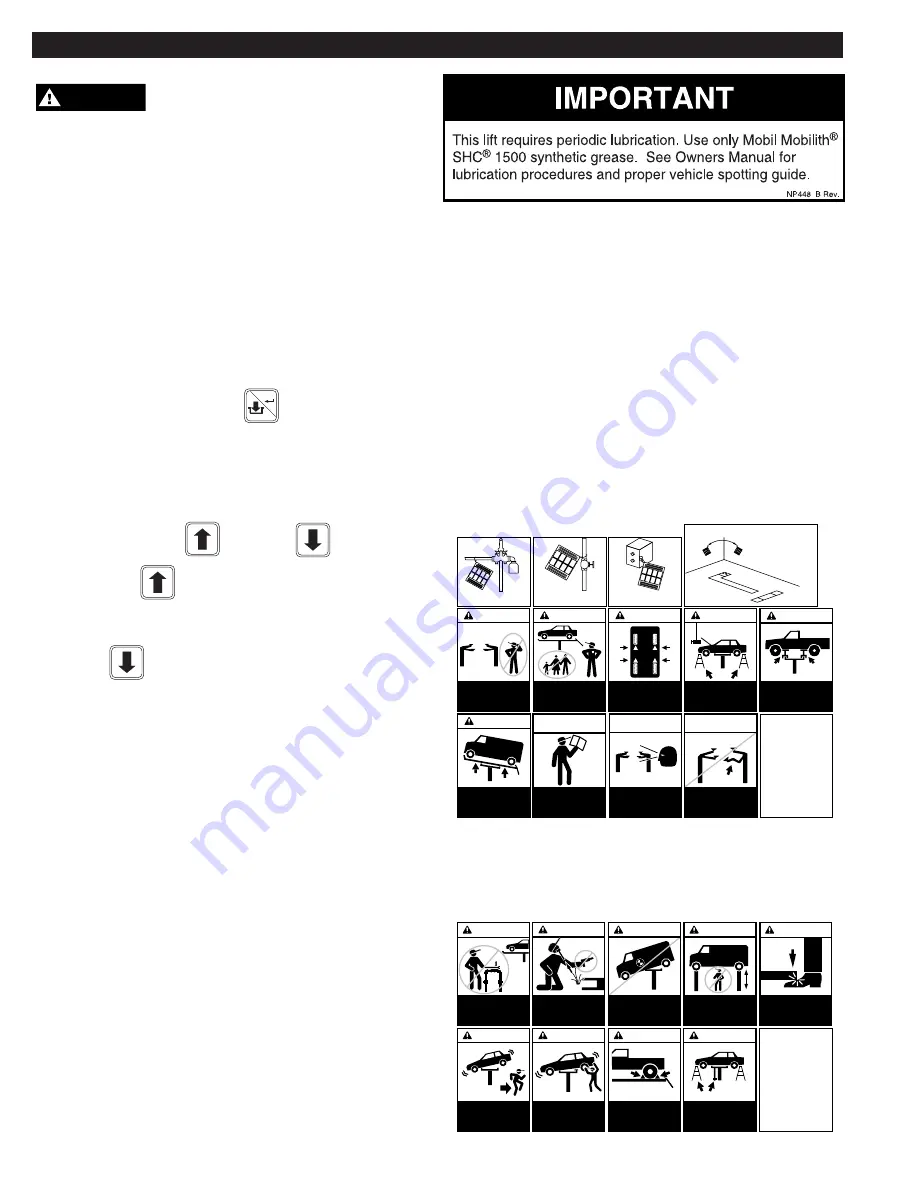

Safety Warning Labels

for Inground Lifts

Lift Owner/User Responsibilities:

A.

This Safety Warning placard, see below, SHALL be

displayed in a conspicuous location in the lift area.

B.

Use one of the mounting arrangements illustrated on

back of this placard.

C.

These Safety Warning labels supplement other docu-

ments supplied with the lift.

D.

Be certain all lift operators read and understand these

labels, operating instructions and other safety related

information supplied with the lift.

CAUTION

Lift to be used

by trained operator

only.

©

? ?

?

CAUTION

Authorized personnel

only in lift area.

©

CAUTION

Use vehicle

manufacturer’s

lift points.

©

CAUTION

Always use

safety stands when

removing or installing

heavy components.

©

Do not operate

a damaged lift.

©

SAFETY

INSTRUCTIONS

Read operating

and safety manuals

before using lift.

©

SAFETY

INSTRUCTIONS

The messages and pictographs

shown are generic in nature and

are meant to generally represent

hazards common to all automotive

lifts regardless of specific style.

Funding for the development and

validation of these labels was

provided by the Automotive Lift

Institute, PO Box 33116 Indialantic,

FL. 32903-3116.

They are protected by copyright.

Set of labels may be obtained from

ALI or its member companies.

ALI/WL500cs

1992 by ALI, Inc.

TYPICAL PLACARD LOCATIONS

STO

P

STAR

T

Air Supply To Lift

Push Button Controls on

Electric Powered Lifts

Wall Mounted Lift

Control

CAUTION

Use height extenders

when necessary

to ensure

good contact.

©

Proper maintenance

and inspection

is necessary

for safe operation.

©

SAFETY

INSTRUCTIONS

CAUTION

Auxiliary adapters

may reduce

load capacity.

©

In-floor Lift Controls:

Locate placard on wall or

column in lift area near lift

controls

WARNING

Do not override

self-closing

lift controls.

©

WARNING

DO NOT remove oil

fill plug before reading

manufacturer's

manuals.

©

WARNING

Position vehicle

center of gravity

over lift.

©

WARNING

Remain clear of lift

when raising or

lowering vehicle.

©

WARNING

Chock wheel

to prevent

vehicle movement.

©

WARNING

Clear area if vehicle

is in danger of falling.

©

WARNING

Avoid excessive

rocking of vehicle

while on lift.

©

The messages and pictographs

shown are generic in nature and

are meant to generally represent

hazards common to all automotive

lifts regardless of specific style.

Funding for the development and

validation of these labels was

provided by the Automotive Lift

Institute, PO Box 33116 Indialantic,

FL. 32903-3116.

They are protected by copyright.

Set of labels may be obtained from

ALI or its member companies.

ALI/WL500w

1992 by ALI, Inc.

SAFETY WARNING LABELS FOR INGROUND LIFTS

Lift Owner/User Responsibilities:

A.

This Safety Warning placard

SHALL

be displayed

in a conspicuous location in the lift area.

B.

Use one of the mounting arrangements illustrated

on back of this placard.

C.

These Safety Warning labels supplement other

documents supplied with the lift.

D.

Be certain all lift operators read and understand

these labels, operating instructions and other

safety related information supplied with the lift.

WARNING

Use lift locking device

or 4 stands

to support vehicle.

©

or

Keep feet

clear of lift

while lowering.

©

WARNING

WARNING

If you are not completely familiar with

automotive lift maintenance procedures

STOP

. Contact factory

for instructions. To avoid personal injury, permit only qualified

personnel to perform maintenance on this equipment.

Always

keep locking latch free and oiled.

Always

keep all bolts tight.

Always

keep superstructure clean. In salt belt or other corrosive

environments, the lift must be washed down weekly.

Always

make sure the perimeter of the guide barrel and center

cover are sealed with a good grade of silicone.

NOTE

Be sure plugs on superstructure's are in place.

Daily

inspect adapters for damage or excessive wear. Replace as

required with genuine Rotary parts.

Daily

check locking latch operation.

If locking latch is not heard when lift is raised:

A.

Lower loaded lift onto lock

SELECT

LOWER TO LOCKS

, to check if lock is

functioning. If lock is functioning, stop. If not, continue on to

"Step B".

B.

Remove center cover and raise unloaded lift to full rise.

C.

Check locking latch for damage or air line problem.

D.

Repair and lubricate locking latch pivot points.

E.

Raise lift off lock

. Lower lift

about half way.

Then raise lift

and watch locking latch operation.

F.

The air cylinder should allow locking latch to pivot in and

out of the latch bar.

G.

Push

to lower lift.

H.

Replace center cover and torque bolts to 60 ft-lbs.

I.

Seal around the perimeter of the guide barrel and center

cover with a good grade of silicone.

Monthly

lubricate lift guide barrels.

Guide Barrel Lubrication:

A.

Each guide barrel has a grease fitting on the top of the

guide barrel.

B.

While raising and lowering unloaded lift, give each guide

barrel 10-12 pumps with "hand" (manual) grease gun using

only Mobil Mobilith

®

SHC

®

1500 synthetic grease.

C.

For your nearest Mobil Mobilith

®

SHC

®

1500 synthetic

grease source, call 1-800-662-4525 or your local Rotary

distributor.

Semi-annually

check fluid level of lift power unit and re-fill if

required per installation instructions using Dexron III ATF or

ISOVG32 Hydraulic Fluid.

Replace

all caution, warning or safety related decals on the lift if

unable to read or missing. Reorder labels from Rotary Lift, see

Safety Warning Labels for Inground Lifts.

Replace

IMPORTANT

decal on outside of yokes if unable to

read or missing. Reorder labels from Rotary Lift, NP448.

MAINTENANCE INSTRUCTIONS