MOUNTING INSTRUCTIONS

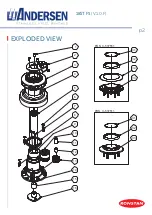

PAWL SPRING MOUNTING

Installing the winch is easy, if you follow these instructions. The numbers in ( ) refer to the

position numbers in the parts list.

Tools required for the installation:

• Allen key (3 mm)

• Allen key (5 mm)

• Ø6.5 mm. (1/4”) drill

• Bedding compound

1. Remove screws (1).

2. Remove self-tailing arm (2) and drum (4).

3. Place the template and drill holes Ø6.5mm (1/4”).

Make sure that no dust comes into contact with the winch while drilling.

4. Apply a light coat of bedding compound, ensuring that each bolt hole is bedded.

Keep drain grooves clear.

5. Fasten base (14) into place using 6 pieces. M6 (1/4”) countersunk head screws.

Use large washers or a backing plate.

6. Assemble in reverse order.

7. Check that the winch is functioning correctly:

- The drum should operate smoothly, by turning the drum clockwise by hand.

- The drum must not turn when trying to turn the drum anti clockwise.

- While turning the winch handle clockwise the drum should turn.

- While turning the winch handle anti clockwise the drum should not turn.

• 6 x M6 (1/4”) countersunk head screws and corresponding

nuts (length depending on deck thickness).

• 6 x large washers or backing plate

• Ring spanner to match nuts

Note the curved

spring “arm”

p4

18ST FS

(V.1.0.F)