Notice originale : Français NT0002 V –p – 03/2014

34

7-

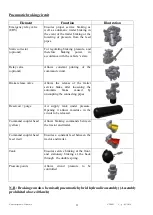

Servicing and maintenance

In order to execute the servicing operations in good conditions, please respect the

following safety rules:

Block the wheels.

Tighten the mechanic brake.

Remove the vehicle from its loading.

1.

Verifying of the braking system (every 6 months)

a-

Parking and rupture brake

Verify the good tension of parking/ rupture brake.

The parking brake lever should not be able to evolve in the last ¼ of its stroke. If this is

not the case, re-stretch the cable.

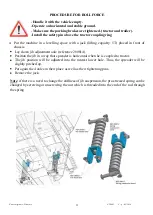

Procedure for cable stretching :

Put the lever of parking brake in rest position and be sure of the vehicle

immobilization by blocking it in the front and in the back of the wheels.

Unfasten the rope clamps from one side

Re- stretch the cable

Fasten again the rope clamps

Do again a test

If the brake rod (see fig1 on next page ) require too much angle in order to

enable an efficient braking, allow for sealing compensation in the trimmings

(see next point : b)

b-

Service Brake

Verify the good condition of brakes cylinders, make sure they are not full-stroke and

control their fixation as well as the one of the retracting springs (the cylinders should not

get off more than two thirds of their maximum stroke, that’s to say: 100mm

If it is not the case, we must

allow for sealing compensation in the brake trimmings.

To do so :

Put the lever of parking brake in rest position and be sure of the vehicle

immobilization by blocking it in the front and in the back of the wheels.

Remove the circlips on end cam brake

(see fig1 on next page)

Detach the link rod cam.

With a pin spanner for example, make a couple in the brake cam to simulate a

braking movement.

Reposition the link rod cam in this position.

Reposition the circlips.

N.B: If your vehicle is equipped with brake cylinders with automatic sealing

compensation, the operation of trimmings sealing compensation will be

carried out automatically.