18

Part Names and Functions

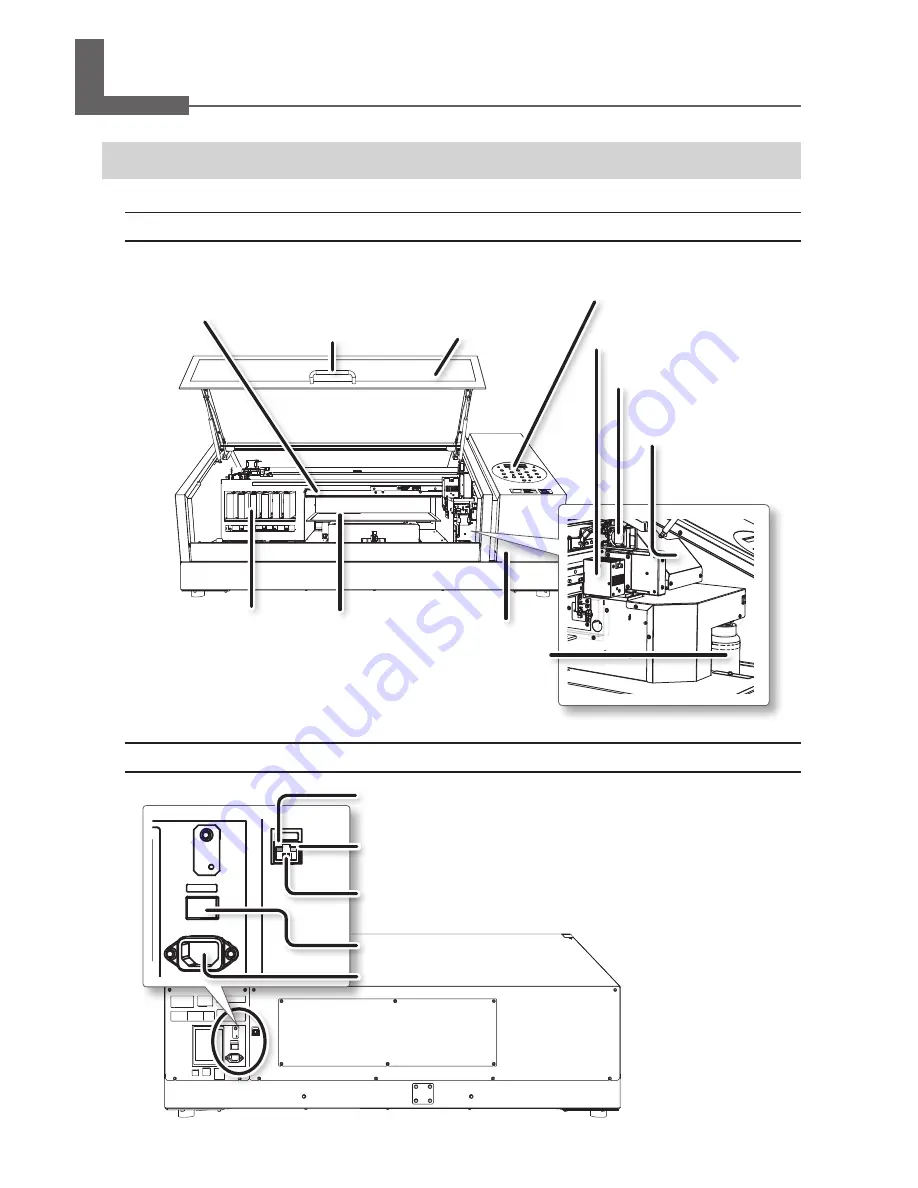

Printer Unit

Front

Cartridge slots

There are where ink

cartridges are installed.

Flat table

Panel cover

Front cover

Keep this closed except

when necessary such as

when loading media.

Handle

Hold this handle to

open and close the

font cover gently.

Operation panel

”Operation Panel” (P. 19)

UV-LED device

Print-head carriage

The print heads are inside

this carriage.

Carriage fan

Spins while printing.

Head gap sensor

Used to detect the height

of media.

Drain bottle

Rear

Main power switch

Status LED

This flashes in yellow while data is being received from the network.

Link LED

This lights in green when the connection to the network is normal.

Ethernet connector

This is used to connect the machine to a network.

Power-cord connector

Summary of Contents for VersaUV LEF-200

Page 52: ...R1 160715...