Installation

Transport System Installation

198

MagneMotion

Rockwell Automation Publication MMI-UM007F-EN-P - September 2020

Motor Sense and Drive Cables

When using a 1 m QSHT motor, there is one Sense cable and one Drive cable that is con-

nected from each inverter to each motor. When using two consecutive 1/2 m QSHT motors,

there are two Sense cables and two Drive cables, one set per motor.

1.

For 1 m motors, connect a drive cable from Stator Inverter Output A and Stator

Inverter Output B on the inverter to the Drive connector on the motor (see

). Tighten the connector on the motor with soft jaw pliers (the connector

snaps into place when it reaches the locked position). Route the cable so it is shielded

from damage and can be easily accessed for service.

For 1/2 m motors, connect a drive cable from Stator Inverter Output A on the inverter

to the Drive connector on the first 1/2 m motor (see

). Connect a drive

cable from Stator Inverter Output B on the inverter to the Drive connector on the sec-

ond (consecutive) 1/2 m motor (see

). Tighten the connector with soft jaw

pliers (the connector snaps into place when it reaches the locked position). Route the

cable so it is shielded from damage and can be easily accessed for service.

The factory-supplied MMI-HT-Series motor cables are shielded and the braided cable

shield must terminate at the inverter during installation as shown in

exposed area must be clamped (with the clamp provided) at the bottom front of the

inverter. Clamp spacers, included with the inverters and held captive by rivets, are

needed for all cable installations, and must not be removed.

A.

Loosen the clamp knob.

The drive cable shield attaches to the inverter cable clamp. Clamp spacers are

included to make sure of a tight fit within the drive clamp.

B.

Position the exposed portion of each cable braid directly in line with the clamp.

C.

Hand tighten the clamp knob.

Make sure that the cable clamp tightens around the cable shield and provides a

good bond between the cable shield and the drive chassis. Only finger-tight

torque on the clamp knob is required. The cable should not move within the

clamp under its own weight or when slight pressure is applied by hand.

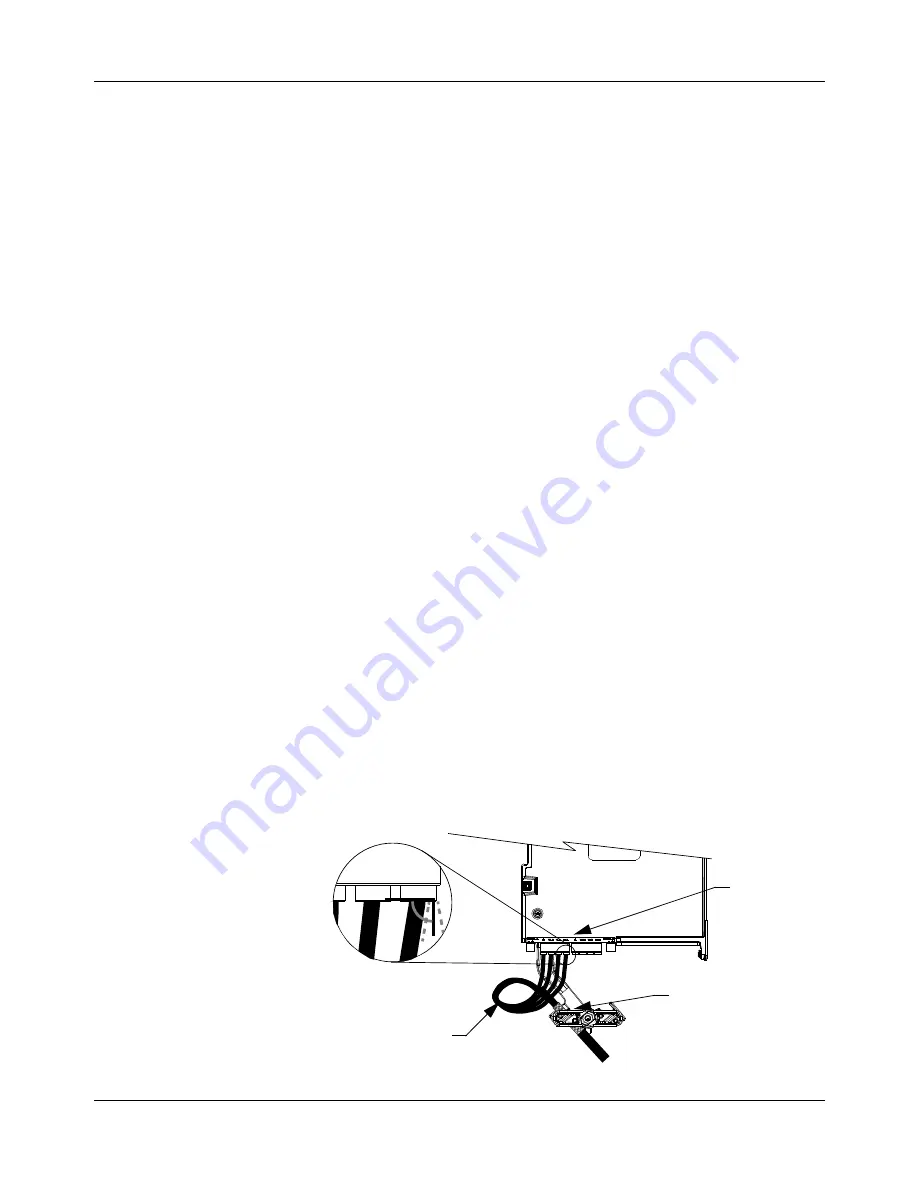

Figure 5-11: QSHT 5700 Inverter Cable Clamp

Service loops provide stress relief

and the conductors enter into the

motor connectors at approximate-

ly 90° (between 75° and 105° is

acceptable).

75° to 105° Entry

into connectors

Clamp compressed

around shield close

to heat shrink tubing

Motor Drive

Connector