SECTION 6: H

EATER

I

NSTALLATION

15

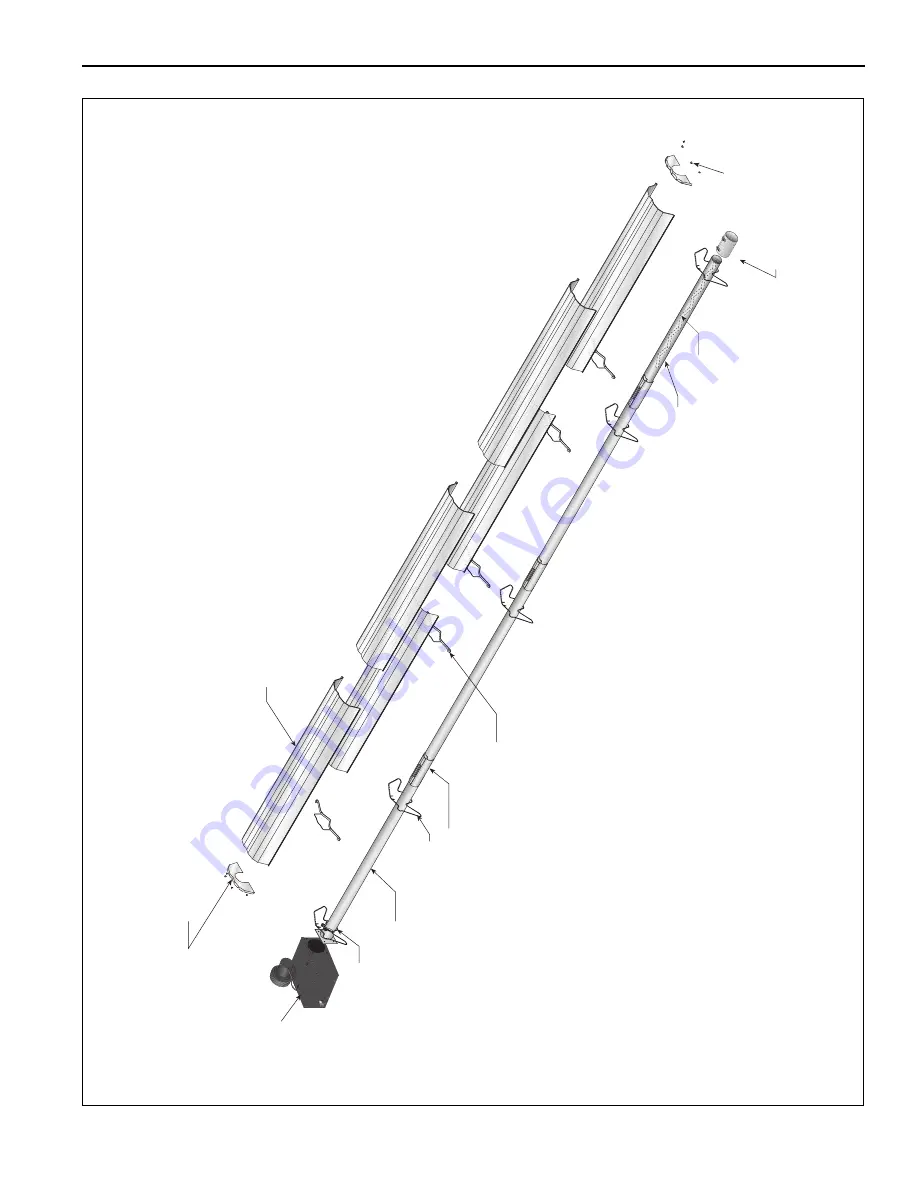

FIGURE 15: Linear Heater Assembly Overview

Tube

R

ef

lect

or

R

ef

lect

or End C

ap

R

ef

lect

or Suppor

t

Bur

ner

C

oupling

U-Clips

Bur

ner

Tube

Tube and R

ef

lect

or Hanger

Tube Clamp

Pa

ckage

Vent

Adapt

er

Turb

ulat

or

(W

ith Select Models)