Visit

www.rmspl.com.au

for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 2/9

ARC FAULT PROTECTION

The over-current caused by an arc is, due to its resistance, lower

than the over-current caused by a “metallic” short circuit. The

over-current caused by the arc may also be lower than the

protection start current when energising circuits or starting large

motors. The consequence of these conditions is that a protection

system based solely on over-current detection cannot effectively

discriminate between normal system currents & an arc fault

condition:

For moderate arc fault currents the trip time of the over-current

IDMT stage will be too slow;

For very low arc fault currents the instantaneous trip stage of a

standard over-current relay cannot be set low enough.

SWITCHGEAR ARC PROTECTION

The risk of arc fault damage exists at the CB cable termination &

in the CB chamber itself. The CB cable termination is particularly

at risk to ingress of moisture & rodent damage.

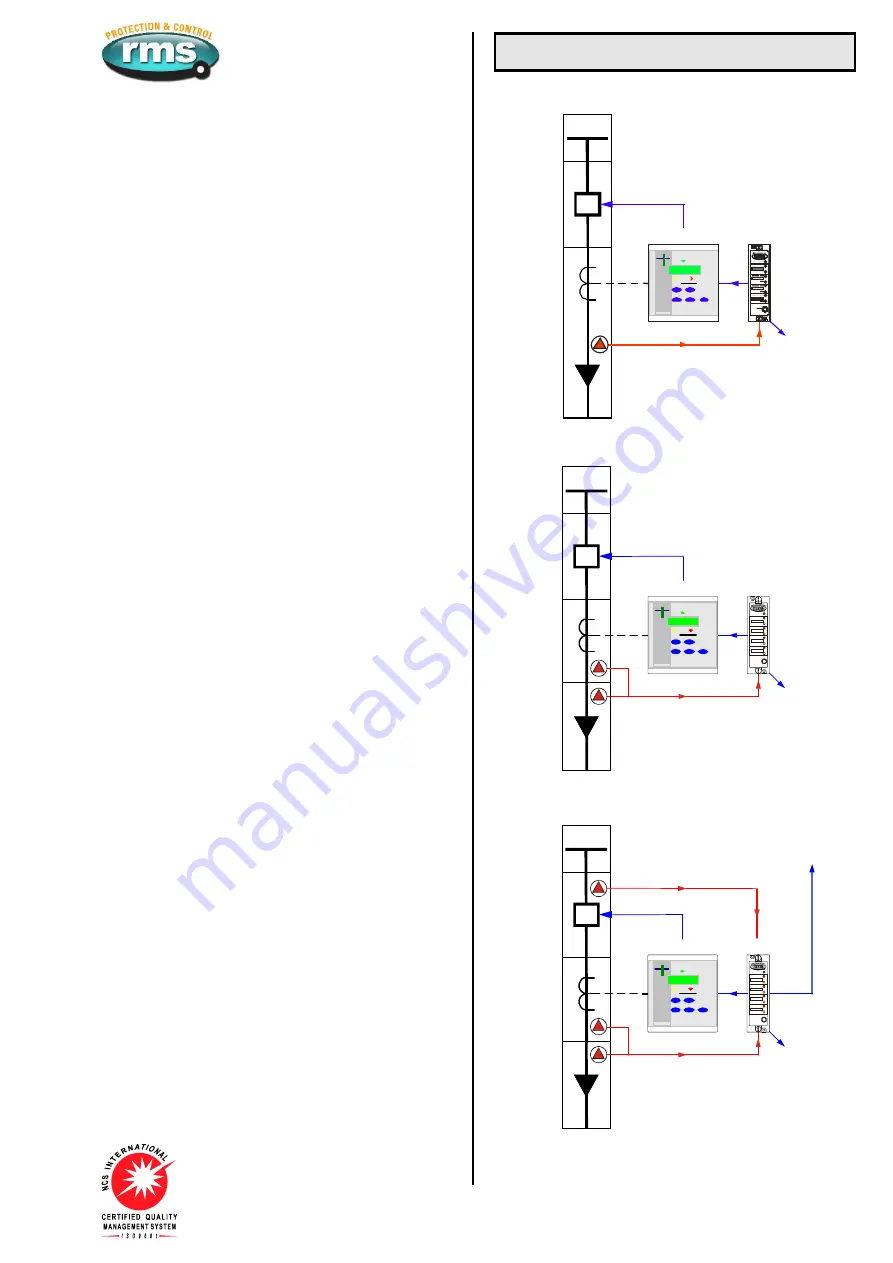

The 1S25 Arc Fault Monitor provides four (4) independent

tripping zones with one or two arc sensors per zone as depicted

in the single line application diagrams at right.

Figures 1 & 2 depict arc protection of up to four feeder circuits

with a single 1S25 as independent zones. A trip signal will be

initiated to the circuit breaker in the event of an arc fault occurring

at the sensor(s) within its zone provided the overcurrent relay

starter contact is picked up. In these applications the overcurrent

check stage is optional as the consequence of a single feeder

outage is less than the loss of an entire BUS.

Figure 3 shows an application where a 1S25 is applied for the

protection of the Cable box, CT chamber & CB chamber across

two feeder circuits (Zones). In this configuration one arc trip zone

is used to trip the feeder circuit breaker in the event of an arc

fault in the cable box or CT chamber. The second zone trip

output is wired to trip the upstream BUS breaker (BUS

overcurrent check not shown), in the event of an arc fault in the

CB chamber.

EXISTING SWITCHGEAR APPLICATIONS

The existing overcurrent relay protecting the feeder will normally

provide an independent output contact associated with the start

current setting of the relay. That is an output contact that will

close when a phase or earth fault current is detected above the

threshold which starts the internal relay timers. This starter

element should be set for instantaneous operation so that it will

pick up in the order of 15ms.

An Arc Fault Monitor relay 1S25 is installed on the switchgear

panel adjacent to the protection relay.

1S30 optical arc sensors are fitted in the cable termination box &

CT chamber as depicted in figure 2.

The overcurrent relay starter contact may optionally be wired in

series with the arc fault detection trip output contact as depicted

in figure 8. The resulting “AND” function trip output is wired to trip

the breaker in ~15ms in the event that an arc fault is detected

while the overcurrent start element is picked up.

The common arc trip & fail alarm contacts may be employed for

interface to a SCADA system for fault reporting.

NEW SWITCHGEAR APPLICATIONS

For new switchgear installations a modern numeric feeder

protection relay is likely to be employed which will have

numerous programming & configuration options.

The basic concept is the same as for the existing switchgear

application described above except that the additional features &

flexibility of modern feeder protection relay allows improved

system integration.

This may be achieved by using the common arc trip output

contact to interface to a programmable status input on the feeder

protection relay. Depending on the model of protection relay

being used this input may be programmed to provide an alarm

message on the HMI, time stamped event record available via its

communications link.

Switchgear Applications

ZONE 1

ARC PROTECTION

COMMON

ALARM

OUTPUT

1S25

50/51

Figure 1: Single arc sensor per zone 1 - Cable box

ZONE 1

ARC PROTECTION

COMMON

ALARM

OUTPUT

1S25

50/51

HEALTH Y

Z ONE 2

Z ONE 3

Z ONE 4

Z ONE 1

Cus tom te xt

Cus tom te xt

Cus tom te xt

Cus tom te xt

FAIL

FAIL

FAIL

FAIL

T RIP

T RIP

T RIP

T RIP

RESET

/T EST

Figure 2: Two arc sensors per zone - Cable box & CT chamber

ZONE 1

ARC PROTECTION

COMMON

ALARM

OUTPUT

1S25

50/51

HEALTH Y

Z ONE 2

Z ONE 3

Z ONE 4

Z ONE 1

Cus tom te xt

Cus tom te xt

Cus tom te xt

Cus tom te xt

FAIL

FAIL

FAIL

FAIL

T RIP

T RIP

T RIP

T RIP

RESET

/T EST

ZONE 2 TRIP

UP STREAM

BREAKER

ZONE 2

ARC PROTECTION

ZONE 1 TRIP

Figure 3: Two arc sensors in zone 1 - Cable box & CT chamber

One or two arc sensors in zone 2 for CB chamber