35-3010A-13 Sample-Draw Detector • 17

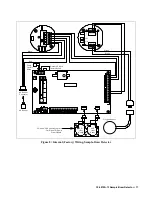

Figure 8: Internal (Factory) Wiring, Sample-Draw Detector

W hit e

SPAN

Z ER O

G

OX Y

BK

W

R D

OX Y

T OX IC

T OX IC

24 V

4/2 0

+

+

F B

TP

-

B A TT

TP

+

Pressure S w itc h

F actory W ired

H2S

(Not

Used)

CO

(N ot

Used)

Pum p

F actory

W ired

G reen

W hit e

R ed

H2 S ensor

C onnector

H2 S ensor

G reen

Black

CO and H2S S ensors Plug I nto

F ar S ide of P reamp

Circuit B oard

IN

S

T

R

U

M

EN

T

S

SE

N

S

O

R

G RN

T P -

B L K

S P AN Z E RO

PO

W

E

R

/S

IG

P /N 57 -10 50RK

RE V . 0

T P +

G ND

2 4V

4 -2 0

R E D

W H T

O xy gen S ensor