18

Possible Causes:

Grip Range of Rivet Nut is too long

Low Air Pressure

Insufficient Hydraulic Oil leads to Stroke decreased

Air bubbles in Hydraulic Oil

Oil Cylinder (15) leaks

Improper assembly of Valve Assembly (43AY)

Worn O-Rings in Valve Assembly (43AY)

Solutions:

Check suitable Grip Range of Rivet Nut to match work

piece’s thickness. It is nothing to do with Stroke of Tool

Check Compressed Air Supply System, adjust Air Pressure to in

specification, check Air Cylinder (30) leak and replace it if necessary,

clean Air Cylinder (30) inside, clean or replace O-Rings (53, 58, 60)

Refill Hydraulic Oil through Oil Refill Hole, see 11.5 solutions

Bleed Oil from Air Cylinder (30), and refill New Hydraulic Oil

See below 12.9 solutions

Reassemble Valve Assembly (43AY)

Replace all O-Rings (42, 44, 29, 47, 50)

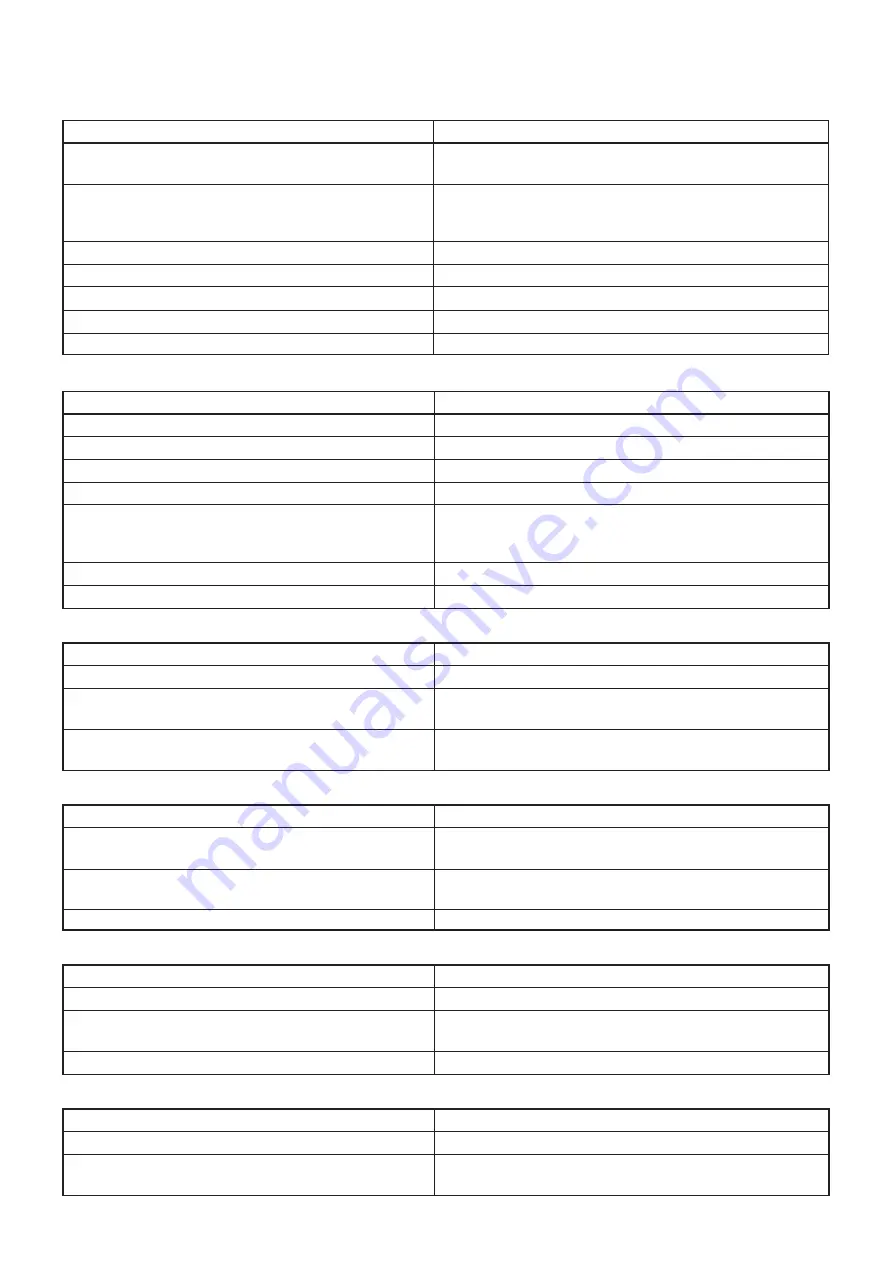

12.7 MALFUNCTION: No operation after triggering (Stroke lost), or more than one operation of Trigger to

fasten Rivet Nut (Stroke decreased)

12.9 MALFUNCTION: Oil Cylinder (15) leaks Hydraulic Oil

Possible Causes:

Oil Cylinder (15) damaged

Improper assembly of O-Rings (13, 19, 27, 29) and Back-Up

Rings (14, 20, 28) in front & rear ends of Oil Cylinder (15)

Worn O-Rings (13, 19, 27, 29) and Back-Up Rings (14, 20,

28) in front & rear ends of Oil Cylinder (15)

Solutions:

Replace a new Oil Cylinder (15)

Reassemble O-Rings (13, 19, 27, 29) and Back-Up Rings

(14, 20, 28) in front & rear ends of Oil Cylinder (15)

Replace new O-Rings (13, 19, 27, 29) and Back-Up Rings

(14, 20, 28) in front & rear ends of Oil Cylinder (15)

12.11 MALFUNCTION: Valve Assembly (43AY) and Noise Silencer (33) leak Air

Possible Causes:

Improper assembly of Valve Assembly (43AY)

Worn O-Rings (42, 44, 29, 47, 50) in Valve Assembly (43AY)

Weak Springs (45, 49) in Valve Assembly (43AY)

Solutions:

Reassemble Valve Assembly (43AY)

Replace new O-Rings (42, 44, 29, 47, 50) in Valve

Assembly (43AY)

Replace new Springs (45, 49) In Valve Assembly (43AY)

12.12 MALFUNCTION: Air Inlet and Air Inlet Fitting leak Air

Possible Causes:

Wrong thread size of Air Inlet Fitting

Air Inlet thread damaged

Solutions:

Change correct thread size of Air Inlet Fitting

Tap thread and wrap Tape Seal around Air Inlet

Fitting’s male thread

12.10 MALFUNCTION: Air Cylinder (30) and Noise Silencer (33) leak Hydraulic Oil

Possible Causes:

Improper assembly of O-Rings (27, 29) and Back-Up Ring

(28) in lower end of Oil Cylinder (15)

Worn O-Rings (27, 29) and Back-Up Ring (28) in lower

end of Oil Cylinder (15)

Worn Lock Nut O-Ring (32A)

Solutions:

Reassemble O-Rings (27, 29) and Back-Up Ring (28) in

lower end of Oil Cylinder (15)

Replace new O-Rings (27, 29) and Back-Up Ring (28) in

lower end of Oil Cylinder (15)

Replace New Lock Nut O-Ring (32A)

12.8 MALFUNCTION: Slow operation or no operation of Air Piston Assembly (55AY) in Air Cylinder (30)

Possible Causes:

Improper assembly of Valve Assembly (43AY)

Worn O-Rings in Valve Assembly (43AY)

Improper assembly of Air Piston Assembly (55AY)

Worn Air Piston Ring (53) and Buffer Ring (52)

Low Air Pressure

Noise Silencer (33) blocks air exhaust

Weak or broken Return Springs (21 & 22)

Solutions:

Reassemble Valve Assembly (43AY)

Replace all O-Rings (42, 44, 29, 47, 50)

Reassemble Air Piston Assembly (55AY)

Replace Air Piston Ring (53) and Buffer Ring (52)

Check Compressed Air Supply System, adjust Air Pressure to in

specification, check Air Cylinder (30) leak and replace it if necessary,

clean Air Cylinder (30) inside, clean or replace O-Rings (53, 58, 60)

Clean or replace a new Noise Silencer (33)

Replace new Return Springs (21 & 22)

Summary of Contents for RNT 120

Page 1: ......

Page 6: ...5 7 DIMENSIONS 39 0 UNIT mm 240 3 303 4 91 0 121 4 115 2...