8 Troubleshooting

Ritta l electrical crimping machine R8 E

We reserve the right to make technical m odifications.

25

EN

Cause

Correction

Filling level monitoring active and start

switch pressed too briefly.

◼

Acknowledge the fault: Press touch

display.

◼

Introduce the conductor correctly.

8.3

Ferrules placed too deep in the transport unit

Cause

Correction

The blade cuts in the wire end ferrule:

Current too high, machine switches off.

◼

Switch off the machine.

◼

Start the machine in jogging operation

(see section 6.1 "Jogging operation").

◼

Travel forwards or backwards.

◼

Remove the belt.

◼

Inspect for further damage.

8.4

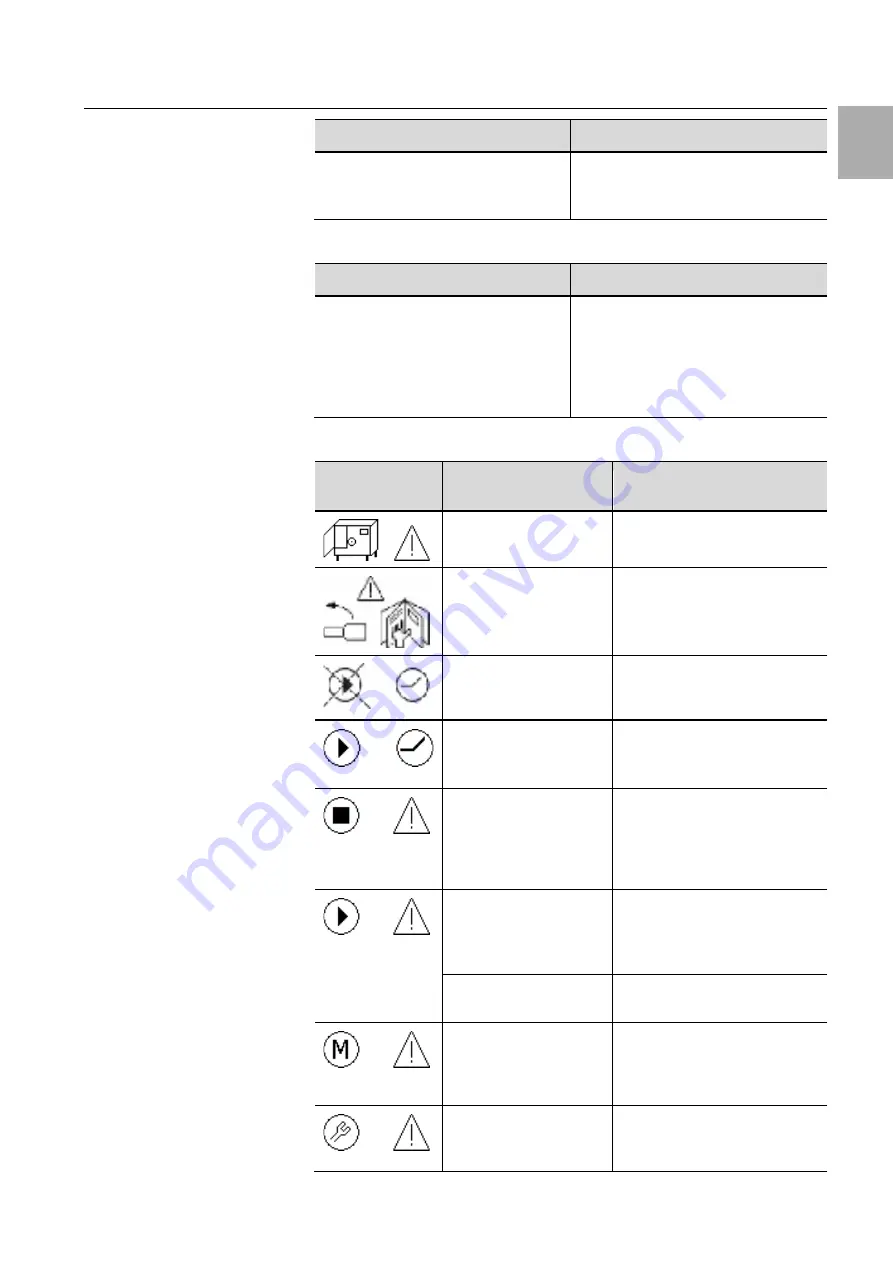

Error messages

Display on touch

display

Cause

Correction

The flap is open.

◼

Close the flap.

Ferrule not removed after

work cycle.

◼

Remove the ferrule (see section

8.5 "Removing the wire end fer-

rule").

Triggering mechanism

pressed too briefly (ma-

chine does not start).

◼

Press the touch display once

briefly.

Triggering mechanism

pressed too briefly (ma-

chine starts).

◼

Press the touch display once

briefly.

◼

Check the crimp quality.

Stop switch fault

–

The stop switch does not

switch.

–

The stop switch is still

pressed.

◼

Press the touch display once

briefly.

Start switch fault

–

Start switch not free.

◼

Check the start switch for block-

age.

◼

Press the touch display once

briefly.

Conductor introduced too

early

◼

Introduce conductor later.

Motor fault

–

The motor does not run

or jams (current too

high).

◼

Press the touch display once

briefly.

Service message

–

Service quantity at-

tained.

Service

◼

Deleted there.