4

Persons carrying out installation work on the Rinnai Infinity Hot Water Package require the following

certificates

For any gas work carried out: Gas Safe Register Registration and ACS certification For installation of

the Hot water system: proof of competence which can be shown through a Registered Operative

Identity Card for the installation of Unvented Domestic Hot Water Systems or the Association of

Installers of Unvented Hot Water Systems (Scotland and Northern Ireland.) For installation of electrical

wiring: EIC certification. IEE 16th Edition

Building Regulation G3 draws attention to the Building Regulations 1991, especially

Regulation 11(1), 12(4), and 13(3). The following is quoted from these and Building Regulation

G3.

A person who intends to carry out building work or to make a material change of use shall-- give to the

local authority full plans and a building notice accompanied by a statement which specifies:

a: the name, make, model and type of hot water storage system to be installed

b: the name of the body, if any, which has approved or certified that the system is capable of

performing in a way which satisfies the requirements of paragraph G3 of Schedule 1.*

c: the name of the body, if any, which has issued any current registered operative identity card to the

installer or proposed installer of the system.

The full plans shall consist of a description of the proposed building work or material change of use,

and the plans, particulars and statements required.

*In the Secretary of State’s view requirement G3 will be met if a hot water storage system that has a

storage vessel with no vent pipe to the atmosphere:

a: has been installed by a competent person

b: has safety devices that prevent the temperature of the stored water at any time exceeding

100°C;

c: has pipework that safely conveys the discharge of hot water from safety devices to where it is visible

but will cause no danger to persons, in or about the building.

The Rinnai Infinity hot water storage system, like most systems over 150 litres capacity, has been

supplied as a package with the necessary safety devices to prevent the temperature of the stored water

from exceeding 100°C. It is the responsibility of the installer to make sure that proper certification has

been gained, and that the system is installed to the requirements of G3 and of this installation manual.

Additionally the installation must be carried out to the requirements of Building

Regulations issued by the Department of the Environment Building Standards

(Scotland) Regulations.

I.E.E. Wiring regulations for electrical installations. BS 6700 Local byelaws Water regulations Health

and safety at work etc. Act 1974

Such other specifications and regulations that may supersede or complement the above documents.

Additional documents listed in the Infinity water heater manual.

Disposal Information:

Under the laws and local regulations, all items must be disposed separately from household waste.

When this product reaches the end of useful life, it should be taken to a collection point identified by

the local authorities. The recycling of the product at the time of disposal will help conserve natural

resources and ensure that it is recycled in a manner that protects human health and environment.

WARNINGS

Summary of Contents for Infinity Series

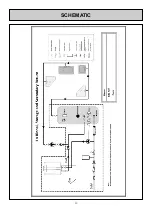

Page 10: ...10 SCHEMATIC ...

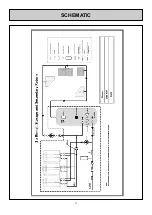

Page 11: ...11 SCHEMATIC ...

Page 15: ...15 300 Litre CYLINDER DIMENSIONS ...

Page 16: ...16 500 Litre CYLINDER DIMENSIONS ...

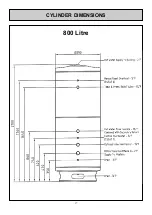

Page 17: ...17 800 Litre CYLINDER DIMENSIONS ...

Page 21: ...21 WIRING DIAGRAM ...

Page 23: ...23 PUMP DATA ...

Page 26: ...26 COMMISSIONING RECORD ...

Page 27: ...27 SERVICE RECORD ...

Page 31: ...31 ...