- 9 -

E

N

G

L

IS

H

1.3

Observe the formation of flue gas (atmospheric

inversion) and draughts when the weather is

unfavourable.

Infeed of too little combustion air can lead to

smoke in the rooms or to flue gas leaks.

Hazardous deposits in the stove and chimney may

also occur.

If flue gas escapes, let the fire burn out and check

whether all the air inlet openings are free and the

flue gas pipes and the stove pipe are clean. If in

doubt notify the master chimney sweep since

draught malfunctions may be connected to your

chimney.

1.4

Push the embers together to form a firebed when

you add new fuel.

1.5

Only use suitable tools when handling embers and

make sure that no embers fall out of the

combustion chamber onto inflammable material.

1.6

Use the equipment supplied to open the doors of

your stove, e.g. heat-resistant gloves.

1.7

Stoves type 1 (BA 1):

These may only be operated with the combustion

chamber door closed.

1.8

The combustion chamber door may only be

opened to add fuel and must then be closed again

otherwise other firing installations connected to the

chimney may be endangered.

1.8.1

The combustion chamber door is to be kept closed

when the stove is not in operation.

1.9

Fouling of the chimney i.e. deposits of highly

inflammable materials such as soot and tar and

subsequently fire in the chimney may occur if wet

fuel is used and operation is damped too much.

If this occurs phone the fire brigade and get

yourself and other residents out of harm’s way.

Note: The size of the combustion chamber door makes

it necessary, particularly with post-heating when

ablaze, not to open the door too abruptly to prevent

the tips of the flames reaching out.

Important information on ROOM-AIR DEPENDENT and

ROOM-AIR INDEPENDENT OPERATION:

Your stove has been tested as a room-air dependent

stove according to EN 13240 and does not conform in

Germany to the requirements for room-air independent

operation. In combination with room-air installations

(e.g. controlled ventilation systems, extractor systems

etc.) it must be ensured that the stove and the room-

air system are monitored and safeguarded mutually

(e.g. via a differential pressure regulator etc.).

The combustion air infeed of approx. 40 m3/h must be

ensured. Please observe the respective local

regulations and rules in consultation with your master

chimney sweep.

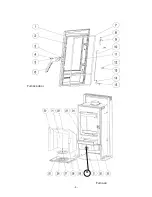

Summary of Contents for tara

Page 1: ...1 TARA Instruction Manual...

Page 2: ...2...

Page 3: ...3 Fitting dimensions...

Page 4: ...4 30 Furnace Furnace door...

Page 5: ...5 50 Panel...

Page 21: ...21...

Page 22: ...22...

Page 24: ...24 Z32829 2011 12 05 G U A R A N T E E G A R A N T I E Customer Client To A Stamp Marque...