20037075

22

GB

Technical description of the burner

3.11

Actuators

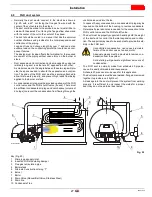

Warning notes

➤

All activities (mounting, installation and service work, etc.)

must be performed by qualified staff.

➤

Before making any wiring changes in the connection area of

the actuator, completely isolate the burner control from the

mains supply (all-polar disconnection).

➤

Ensure protection against electric shock hazard by providing

adequate protection for the connection terminals and by

securing the housing cover.

➤

Check to ensure that wiring is in an orderly state.

➤

Fall or shock can adversely affect the safety functions. Such

units must not be put into operation, even if they do not exhibit

any damage.

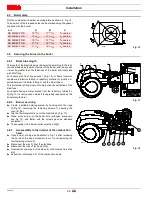

Use

The actuators (Fig. 10) are used to drive and position the air

damper and the gas butterfly valve, without mechanical leverag-

es but via the interposition of an elastic coupling.

When used in connection with burner controls or electronic fuel / air

ratio control, the associated controlling elements are controlled de-

pending on burner output.

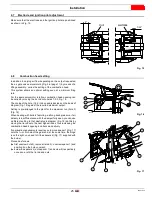

Installation notes

• Always run the high-voltage ignition cables separate from the

unit and other cables while observing the greatest possible dis-

tance.

• To ensure protection against electric shock hazard, make cer-

tain that the AC 230 V section of the actuator is strictly segregat-

ed from the functional low-voltage section.

• The holding torque is reduced when the actuator’s power supply

is switched off.

Technical data

WARNING

To avoid injury to persons, damage to property

or the environment, the following warning notes

should be observed!

Do not open, interfere with or modify the actua-

tors!

WARNING

The housing cover may only be removed for

short periods of time for wiring or when making

the addressing.

It must be made certain that dust or dirt will not

get inside the actuator while such work is car-

ried out.

WARNING

When servicing or replacing the actuators, take

care not to invert the connectors.

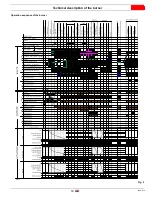

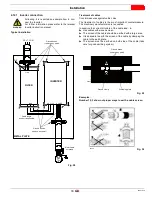

Model

SQM45.295A9

SQM48.497A9

Operating voltage

AC 2 x 12 V via bus cable from the ba-

sic unit or via a separate transformer

Safety class

Extra low-voltage with safe isolation

from mains voltage

Power consumption

9...15 VA

Degree of protection

To EN 60 529, IP 54, provided ade-

quate cable entries are used

On time

50 %, max. 3 min. continuously

Electrical connections

RAST3.5 terminals

Direction

of

rotation

(when facing the shaft)

- Standard: counterclockwise

- Reverse: clockwise

Running time (min.)

for 90°

10 s.

30s.

Holding torque (max.)

1.5 Nm

20 Nm

Nominal torque (max.)

3 Nm

20 Nm

Weight

approx. 1 kg

approx. 1.6 kg

Environmental conditions:

Operation

Climatic conditions

Mechanical conditions

Temperature range

Humidity

DIN EN 60721-3-1

class 1K3

class 1M2

-20...+60 °C

< 95 % r.h.

D8271

Fig. 10

Summary of Contents for RS 300/EV FGR

Page 2: ......