7

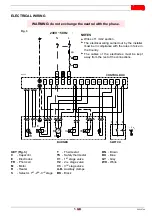

20013744

CN

上表所示燃烧头的设置针对多数情况有效。

通常只能通过风门挡板来调节风量大小。

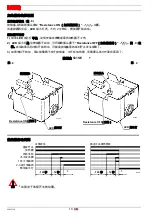

如果在燃烧头

安装好后在燃烧器运行中还想调整燃烧头的设置,用

6mm 的扳手 (2)来旋转调节杆

(1)

,具体操作如下:

向右旋转

: (

标记

+

的方向

)

可以增加进入燃烧室的助燃空气量

,减小风压。烟气中

CO2

含量减小并改善燃烧状况。

(

本设置适用于较低温度点火

)

。

向左旋转

: (

标记

–

的方向

)

可以减少进入燃烧室的助燃空气量

,增加风压。烟气中

CO2

含量增加但火焰贴盘现象减少。

(

本设置不适用于较低温度点火

)

。

设置燃烧头时,实际设定值不要偏离上表中给出的参考值太大(不要超过一个刻度)。调节杆旋转 3 圈相当于

调节 1 个刻度;调节杆末端的孔

(3)

可以帮助识别旋转圈数。

风门挡板调整

:

上表中的设定值的参考条件是:

燃烧器外盖安装并且炉膛背压为 “ 0” 。

这些规则仅供参考。

对于每个具体的燃烧器,由于具有各不相同的工作条件:

实际的喷嘴流量;炉膛内的正或负的背压,

以及不同的过量空气系数等等。从而对风门挡板的设置要求不

同。

安装或不安装燃烧器的外盖,实际的风量会大不相同,认识到这点很重要。

因此建议按如下操作:

按照上表中

(

第

3

点

)

设置风门挡板位置;

盖上外盖,只是简单拧上上面的螺栓;

检查烟气等级;

如果需要改变风量大小,先松开螺栓拆下外盖,调整风门挡板,然后重新盖上外盖后再检查烟气等级。直

到烟气合格。

2

3

6

D5587

1

图 .

5

3