4

TECHNICAL FEATURES

0

It is forbidden to use electrical devices or equipment, such

as switches, appliances, etc. if there is a smell of gas or un-

burnt products. If so:

− ventilate the room, opening doors and windows;

− close the gas valve at the mains;

− immediately call in the Technical Assistance Service or

professionally qualified personnel.

0

It is forbidden to touch the heating unit with bare feet or

parts of the body wet.

0

It is forbidden to start on any technical or cleaning jobs be-

fore disconnecting the heating unit from the power mains.

0

It is forbidden to alter the safety and adjustment devices

without permission and instructions from the heating unit

manufacturer.

0

It is forbidden to obstruct the condensate drain.

0

It is forbidden to pull, detach, twist the wiring coming out of

the heating unit, even if unplugged from the power supply.

0

It is forbidden to obstruct or reduce the size of air vents.

0

It is forbidden to expose the boiler to atmospheric agents (if

it is not a specific unit for outdoors).

0

It is forbidden to leave containers or flammable substances

in the premises where the boiler is installed.

0

Do not dispose of packaging material into the environment,

or leave it within the reach of children, since it can become

a potential hazard. Dispose of packaging material in com-

pliance with applicable legislation.

0

The user is forbidden to open the cupboard containing the

heating unit. Any jobs on the inside of the latter must be

done by the Technical Assistance Service or by qualified per-

sonnel.

0

It is forbidden to discard the product as household waste.

At the end of its service life, it can be consigned to specif-

ic selected waste centres provided by the local authorities

or else to dealers providing this service. Disposing of a do-

mestic appliance separately will prevent possible harmful

consequences for environment and health derived from

inappropriate disposal, likewise making it possible to recu-

perate the materials it is made of with substantial savings in

energy and resources.

3

TECHNICAL FEATURES

3.1

Main features

Condexa Pro3 IN-EXT

is a condensing, modular, pre-mixed,

blown, thermal group; it is made up of a series of

Condexa Pro3

IN-EXT

thermal elements installed in battery.

A unit is made of N° 2, 3 or 4 heat exchangers, each with a mod-

ulating power from 23 ti 115 kW; equipped with climatic regula-

tion and RS485 connection. Each device can be serially matched

up with same tipe units up to a total installed power of 3680

kW (eight

Condexa Pro3 IN-EXT

equal to a total of di 32 heat

exchangers).

9

In case of installation of more than 32 unit (up to 60 unit)

please contact

R

Technical Assistance Service.

It is possible to connect up two thermal groups (with a total of 8

heat exchangers) directly using the internal 5” hydraulic mani-

folds and the internal 3” gas manifold.

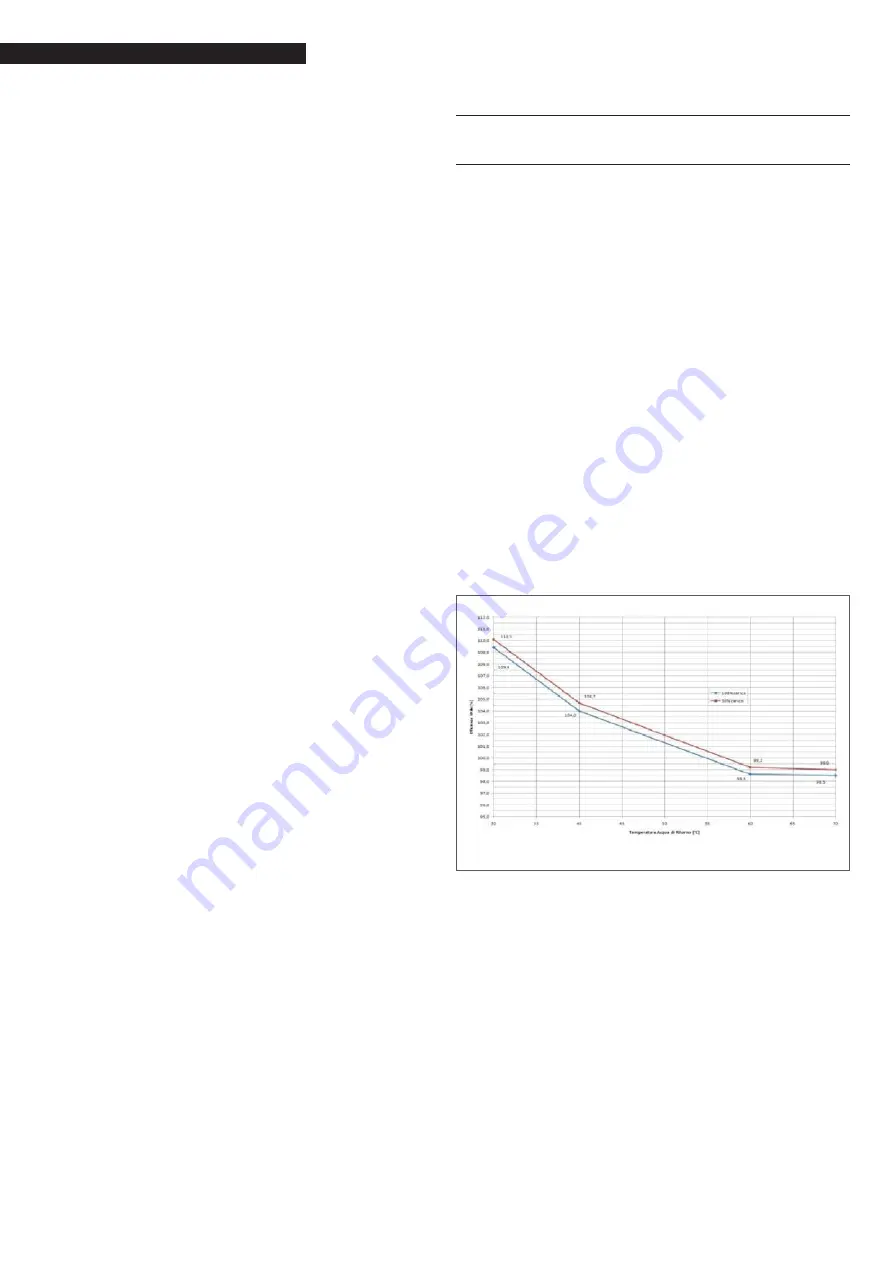

The efficiency of the generators reaches 109% based on the low-

er heat potential of natural gas (Hi) making it possible to use a

flue manifold entirely made of plastic (PP). The system also en-

ables continual modulation of the gas and combustion air flow.

The

Condexa Pro3 IN-EXT

heating unit is the optimum as far as

operating costs (up to 109% efficiency per Hi, see Figure 1) reli-

ability and flexibility. In fact, thanks to the new heat exchang-

er with improved power, to the new electronic management,

to the modularity and versatility, it is possible to make a rapid

connection to any kind of heating system and storage hot water

production.

Figure 1

The insertion of a single thermal element in cascade, over the

traditional rotation of the ignition, can take place with

variable

factor of heating power load

, so that when a certain power

percentage of the first element is reached (e.g. 30%), the suc-

cessive element already starts with the same load factor. This

latter feature allows to share the power supplied inside more

than one heat exchangers with a power/exchange surface ratio

which is particularly favourable for condensation latent heat.

Summary of Contents for Condexa Pro3 230 IN V02

Page 1: ...cod 20060249 rev 10 12 2015 Condexa Pro3 230 345 460 IN EXT EN INSTALLATION INSTRUCTIONS...

Page 36: ...36 WIRING DIAGRAMS 12 WIRING DIAGRAMS...

Page 37: ...37 WIRING DIAGRAMS Valvola 2 vie Circolatore...

Page 42: ...42 WATER IN CENTRAL HEATING SYSTEMS...