20026767

20

Installation

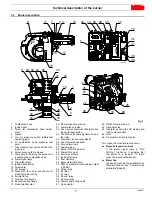

4.10 Gas train

It must be type-approved according to UL Standards and is sup-

plied separately from the burner.

Key to layout

1

Gas input pipe

2

Manual valve

3

Pressure regulator

4

Low gas pressure switch

5

1

st

safety shut off valve

6

2

nd

safety shut off valve

7

Standard issue burner gasket with flange

8

Gas adjustment butterfly valve

9

Burner

4.11

Gas pressure

The Tab. D is used to calculate manifold pressure taking into ac-

count combustion chamber pressure.

Tab. D

Gas manifold pressure measured at test point 1)(Fig. 19), with:

•

combustion chamber at 0” WC;

•

burner operating at maximum output;

•

column 1: gas ring R2-R3)(Fig. 13) adjusted as indicated in di-

agram (Fig. 14);

•

column 2: pressure loss at gas butterfly valve 8)(Fig. 18) with

maximum opening: 90°.

Calculate the approximate maximum output of the burner as fol-

lows:

subtract the combustion chamber pressure from the gas pres-

sure measured at test point 1)(Fig. 19);

find the nearest pressure value to your result in column 2 for

the burner in question;

read off the corresponding output on the left.

Example with natural gas G20

–

Maximum output operation

–

Gas ring 2-5)(Fig. 13) adjusted as indicated in diagram

(Fig. 14)

–

Gas pressure at test point 1)(Fig. 19)

= 3.69“ WC

–

Pressure in combustion chamber

= 0.79“ WC

3.69 - 0.79

= 2.90“ WC

A maximum output of 1136 MBtu/hr shown in Tab. D corresponds

to 2.90” WC pressure, column 1.

This value serves as a rough guide, the effective delivery must be

measured at the gas meter.

WARNING

See the accompanying instructions for the ad-

justment of the gas train.

Fig. 18

D2294

GAS PILOT LINE

MAIN GAS LINE

MBtu/hr

kW

p (“WC)

1

2

720

211

1.38

0.12

949

278

2.16

0.15

1136

333

2.90

0.19

1327

389

3.66

0.23

1515

444

4.21

0.27

1706

500

4.72

0.31

1894

555

5.12

0.35

2085

611

5.31

0.39

Fig. 19

D2786

Summary of Contents for C9541400

Page 2: ......

Page 30: ...20026767 28 Appendix Spare parts A Appendix Spare parts...

Page 35: ......