Installation

21

2916050

GB

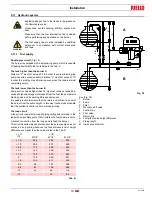

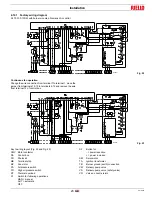

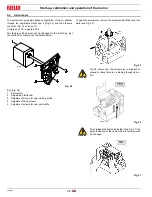

4.11.4 Pump

Technical data

Tab. L

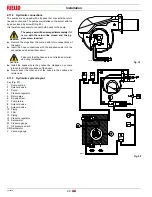

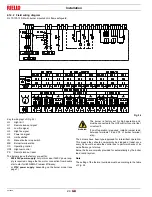

Pump priming

The time required for this operation depends upon the diameter

and length of the suction tubing.

If the pump fails to prime at the first starting of the burner and the

burner locks out, wait approx. 15 seconds, reset the burner, and

then repeat the starting operation as often as required.

After 5 or 6 starting operations allow 2 or 3 minutes for the trans-

former to cool.

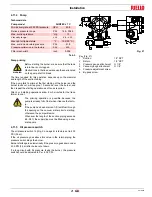

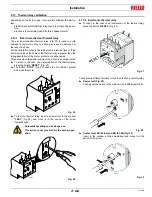

4.11.5 Oil pressure switch

The oil pressure switch 15)(Fig. 3 on page 9) is factory set to 43.5

PSI (3 bar).

If the oil pressure goes above this value in the return piping, the

pressure switch stops the burner.

Burner starts again automatically if the pressure goes down under

43.5 PSI (3 bar) after burner shut down.

If a loop circuit with Px pressure feeds the burner, the pressure

switch should be adjusted to Px + 43.5 PSI.

Suction

1/2” NPT

2

Return

1/2” NPT

3

Pressure gauge attachment

G 1/8”

4

Vacuum gauge attachment

G 1/8”

5

Pressure adjustment screw

6

By-pass screw

Pump model

SUNTEC J7 C

Min. delivery rate at 290 PSI pressure

GPH

60.8

Delivery pressure range

PSI

145 - 304.5

Max. suction pressure

“Hg

13

Viscosity range

cSt

2.8 - 200

Max light oil temperature

°F

194 (90 °C)

Max. suction and return pressure

PSI

21.8

Pressure calibration in the factory

PSI

290

Filter mesh width

inch

0.006

WARNING

Before starting the burner, make sure that the tank

return line is not clogged.

Obstructions in the line could cause the seal located

on the pump shaft to break.

CAUTION

The priming operation is possible because the

pump is already full of fuel when it leaves the facto-

ry.

If the pump has been drained, fill it with fuel through

the opening on the vacuum meter prior to starting;

otherwise, the pump will seize.

Whenever the length of the suction piping exceeds

66 - 98 ft, the supply line must be filled using a sep-

arate pump.

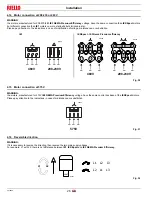

D2352

Fig. 21