1544

7

GB

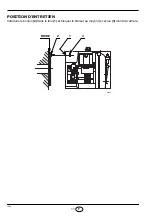

COMBUSTION ADJUSTMENT

In conformity with Efficiency Directive 92/42/EEC the application of the burner on the boiler, adjust-

ment and testing must be carried out observing the instruction manual of the boiler, including verifica-

tion of the CO and CO

2

concentration in the flue gases, their temperatures and the average

temperature of the water in the boiler.

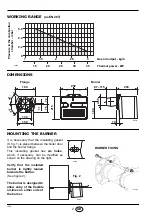

To suit the required appliance output, fit the nozzle then adjust the pump pressure, the setting of the

combustion head and the air damper opening in accordance with the following schedule.

NOZZLES RECOMMENDED :

Monarch type R

Delavan

type W

(till 0,65 GPH)

Delavan

type B

(from 0,65 GPH)

Steinen

type Q

Danfoss type S

Satronic type S

Fluidics

type SF

PRESSURE:

12 bar :

The pump leaves the factory set at this value.

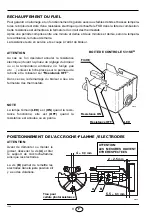

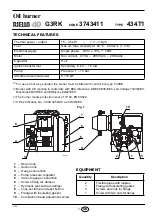

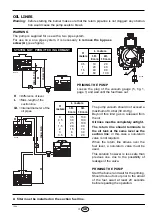

COMBUSTION HEAD SETTING

: This is done when fitting the nozzle, with the blast tube

removed. It depends on the output of the burner and is

carried out by rotating the regulating rod, till the terminal

plane of the blast tube is level with the set-point, as indi-

cated in the schedule.

Nozzle

Pump pressure

Burner output

Comb. head

adjustment

Air damper

adjustment

GPH

Angle

bar

kg/h

±

4%

Set-point

Set-point

0.40

60

°

/ 80

°

10

1.3

0

2.2

0.50

60

°

12

1.8

0.5

3

0.60

60

°

12

2.3

1

4

0.65

60

°

12

2.5

1.5

3.8

0.75

60

°

13

3.0

2

8

1

2

3

4

1

2

3

D5663

5

6

4

2

0

3

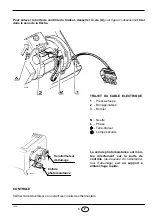

In the sketch on the left, the combustion

head is set for an output of 0.65 GPH

at 12 bar, while the shutter is level with

set-point 1.5, as required by the above

schedule.

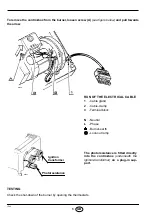

Blast tube

Shutter

Terminal plane of the blast tube

Regulating rod