20040170

22

GB

Installation

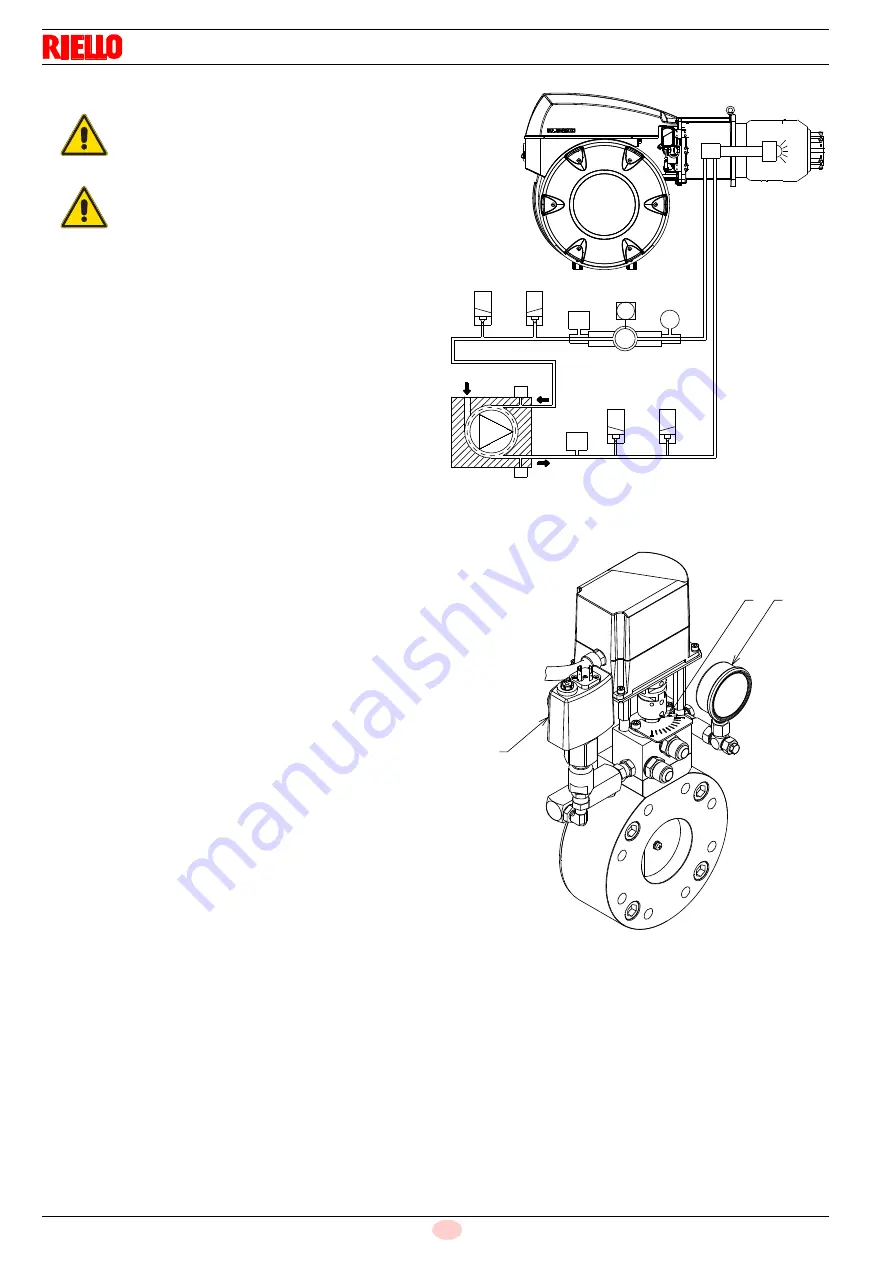

5.11.3 Hydraulic connections

5.11.4 Hydraulic circuit diagram

Key (Fig. 18)

1

Pump suction

2

Pump return line and nozzle return line

3

Pump pressure regulator

4

Delivery safety valve

5

Delivery safety valve

6

Nozzle delivery line

7

Nozzle without interception rod

8

Nozzle return line

9

Pressure variator on nozzle return line

10 Pressure variator servomotor

11 Pressure switch on nozzle return line

12 Safety valve on nozzle return line

13 Safety valve on nozzle return line

14 Pressure switch on pump delivery line

M

Pressure gauges

V

Vacuometer connection

OPERATION

Pre-purging phase

:

valves 4), 5), 12) and 13) closed.

Ignition and operation phase

:

valves 4), 4), 12) and 13) open.

Stop:

All valves closed.

5.11.5 Pressure variator

The pressure variator (Fig. 19), incorporated in the oil circuit

valve group, makes it possible to vary the pressure on the nozzle

return line depending on the output required.

The pressure on the return line is adjusted by varying a section

by means of the rotation of the servomotor 23)(Fig. 5), which also

controls the gas butterfly valve at the same time.

Regulator to 0° (maximum opening) = minimum pressure on

nozzle return line.

Regulator to 90° (minimum opening) = maximum pressure

on nozzle return line.

The servomotor is controlled by the electronic cam 3) (Fig. 6);

thanks to this device, it is possible to set different curves for oil

and gas on the same servomotor (also for the air damper servo-

motor 4)(Fig. 5).

When

adjusting the gas

, it is recommended to adjust the

servomotor to about 90° to reduce leaks from the gas butter-

fly valve.

When

adjusting the oil

, the adjustment is done based on

the nozzle fitted and on the required degree of modulation;

in a situation of minimum firing rate, a rotation of 20° can be

enough.

Key (Fig. 19)

1

Nozzle return pressure gauge

2

Position indicator (0 ÷ 90) of the pressure variator

3

Maximum oil pressure switch on return circuit

CAUTION

Make sure that the flexible hoses to the pump

supply and return line are installed correctly.

WARNING

Follow the instructions below:

Tighten the flexible hoses with the supplied

gaskets.

Take care that the hoses are not stretched or

twisted during installation.

Place the pipes so that they are not crushed

or are in contact with hot parts of the boiler

and so it is possible to open the burner.

Finally, connect the other end of the flexible

hoses to the suction and return pipes.

M

P

M

V

1

4

5

P

9

10

11

12

13

14

8

7

6

V

2

Fig. 18

D11313

1

2

3

Fig. 19

D11322

Summary of Contents for 1311 T2

Page 2: ...Translation of the original instructions...

Page 46: ...20040170 44 GB Appendix Electrical panel layout 0 0 0 0 0 0 0 0...

Page 47: ...45 20040170 GB Appendix Electrical panel layout...

Page 49: ...47 20040170 GB Appendix Electrical panel layout...

Page 51: ...49 20040170 GB Appendix Electrical panel layout 0...

Page 52: ...20040170 50 GB Appendix Electrical panel layout 0 1 1 1 2 1 3 1 1 1 1 1 1 1 41 4 4 1 1 2 1...

Page 53: ...51 20040170 GB Appendix Electrical panel layout 0 0 1 2 0 0 3 3 3 0 1 4...

Page 57: ...55 20040170 GB Appendix Electrical panel layout 01 233 23 4 4 4 5 4 6 4 4 4 4 4 4 4 4 4 4 5 4...

Page 59: ......