PJ X5360N

PJ WX5350N

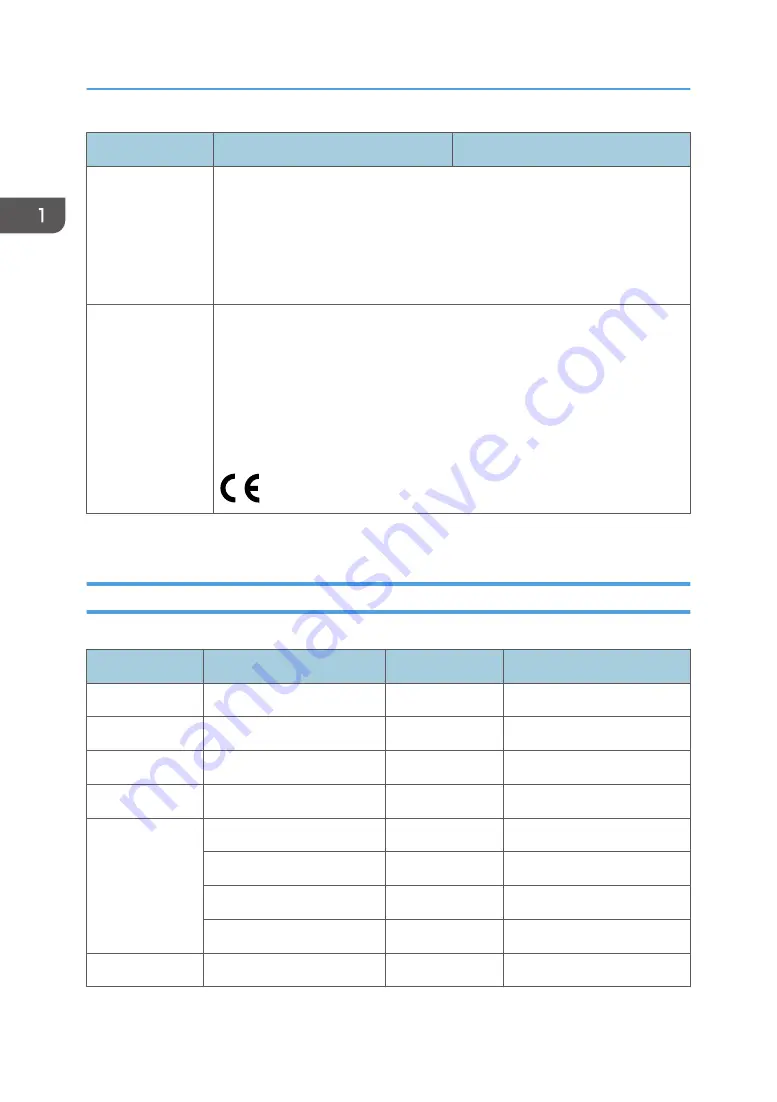

Environmental

Considerations

Operational Temperatures : 41° to 104°F (5° to 40°C),

(ECO mode selected automatically at 95°F to 104°F/35°C to 40°C)

20% to 80% humidity (non-condensing)

Storage Temperatures : 14° to 122°F (-10° to 50°C),

20% to 80% humidity (non-condensing)

Regulations

UL/C-UL Approved (UL 60950-1, CSA 60950-1)

Meets DOC Canada Class B requirements

Meets FCC Class B requirements

Meets AS/NZS CISPR.22 Class B

Meets EMC Directive (EN55022, EN55024, EN61000-3-2, EN61000-3-3)

Meets Low Voltage Directive (EN60950-1, TÜV Approved)

The specifications are subject to change without notice.

List of Supported Signals

Analog RGB

Signal

Resolution ( dots )

Aspect Ratio

Refresh Rate ( Hz )

VGA

640 × 480

4 : 3

60/72/75/85/iMac

SVGA

800 × 600

4 : 3

56/60/72/75/85/iMac

XGA

1024 × 768

*1

4 : 3

60/70/75/85/iMac

XGA+

1152 × 864

4 : 3

60/70/75/85

WXGA

1280 × 768

*2

15 : 9

60

1280 × 800

*2

16 : 10

60

1360 × 768

*3

16 : 9

60

1366 × 768

*3

16 : 9

60

Quad-VGA

1280 × 960

4 : 3

60/75

1. Appendix: Specifications

6

Summary of Contents for PJ WX5350

Page 1: ...Model Rigel PJ1 nx nw Machine Codes Y015 Y016 Field Service Manual 6 January 2012...

Page 2: ......

Page 10: ...8...

Page 20: ...1 Product Information 18...

Page 25: ...Installation Requirements 23...

Page 26: ...2 Installation 24...

Page 34: ...Filters 1 Remove the Filter cover 2 Remove the Filters 3 Replacement and Adjustment 32...

Page 38: ...Rear Panel and Speaker 1 Top cover p 33 3 Replacement and Adjustment 36...

Page 55: ...3 Remove the bracket A 2 4 Remove the screw 1 5 Remove the barrier Parts Replacement 53...

Page 57: ...PSU Fan 1 Remove the Exhaust fan cover p 51 Parts Replacement 55...

Page 135: ...For Audio Does not output sound from the speaker Troubleshooting Guide 133...

Page 138: ...Service Information Reset Not related to the menu mode 5 Troubleshooting 136...

Page 143: ...Model Rigel PJ1 Machine Codes Y015 Y016 Appendices 6 January 2012...

Page 145: ...2...

Page 153: ...MEMO 10...

Page 154: ...MEMO 11...

Page 155: ...MEMO 12 EN...