VI. TROUBLE SHOOTING

Caution

: For safety reasons, only qualified technicians are allowed to work on this unit if there’s an electrical

failure. It is strongly recommended that, under all circumstances, you should contact the manufacturer, your

authorized dealer or take this manual and your unit (if out of warranty) to a certified professional for diagnoses.

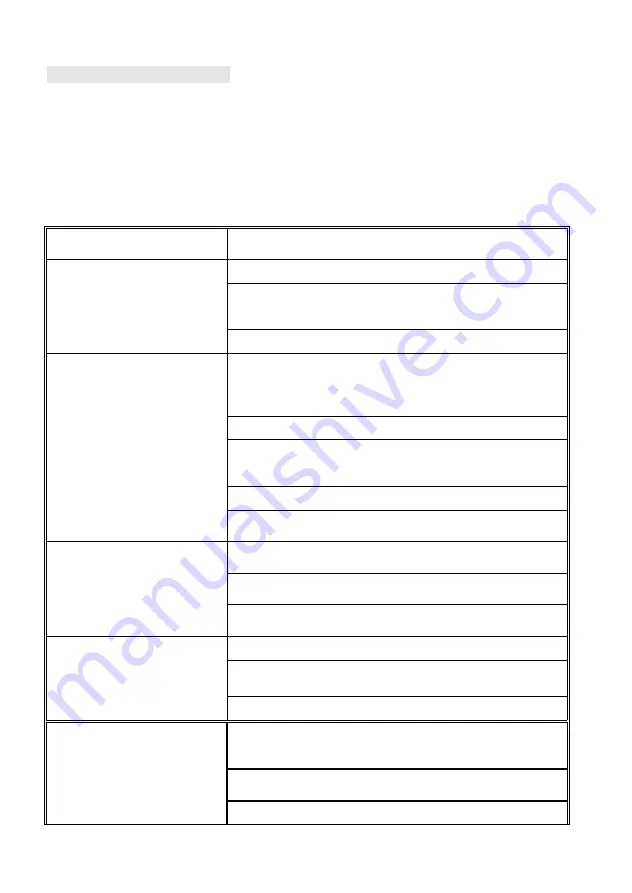

6-1 CT312 Trouble-Shooting

Problems

Possible Causes

1. Main power switch is on, but

no power pilot light, no fan, and

no welding output.

1. Power switch is faulty.

2. No AC power or insufficient power to the unit from the wall

outlet.

3. Internal power supply failure or blown fuse.

2. Power switch is on, the fan

does not run, and there is no

welding output.

1. Voltage of power supply is too high and over-voltage protection

is triggered.

2. Frequency transformer broken.

3. Voltage of power supply is too low and low-voltage protection is

triggered.

4. Wire from the switch to the bottom board loose.

5.

Relay on the bottom board damaged.

3. Fan kicks on, but no HF arc-

striking, can not start the arc, and

abnormal pilot light is not on.

1. Possible short-circuit or loose connection of bridge wire.

2. One of the four capacitors on the bottom board is faulty.

3. Assistant power supply is abnormal (should be DC24V).

4. Abnormal pilot light is off, has

sound of are-striking, but no

welding and cutting output.

1. Welding cable damaged.

2. Earth ground cable damaged or not connected to the work piece.

3. Loose connection to the “+”output terminal.

5. Abnormal pilot light not on, no

sound of arc-striking.

1. Loose connection of the main wire between the transformer and

the power board.

2. Nozzle is oxidized or too far away from work piece.

3. Operation mode switch for MMA/CUT damaged.

14