IQ plus 210 Installation Manual

6

Visit our website

3. Next, measure –EXC to +SIG and –EXC to –SIG. Measured values between the excitation line and each of the signal

lines should be within 2–3

.

4. If the +EXC measurements (step 2) are Š 5% larger than the –EXC measurements (step 3), set the compensation

jumper in the ON position. If the +EXC measurements are < 5% greater (or are less) than the –EXC measurements,

set the jumper in the OFF position.

2.3.4 Serial Communications

To attach serial communications cables, connect communications cables to connector J7 as shown in Table 2-3. Use cable ties

to secure serial cable to the inside of the enclosure.

Use the SERIAL menu to configure serial communications. See

for configuration information.

2.3.5 Digital Inputs

Digital inputs (connectors J2 and J3) can be used to perform remote ZERO and UNITS key presses or to send serial data to a

printer (remote PRINT key function). The inputs are active (on) with low voltage (0 VDC) and can be driven by TTL or 5V logic

without additional hardware. Use the DIG IN menu to configure the digital inputs. See

for information

about configuring the digital inputs.

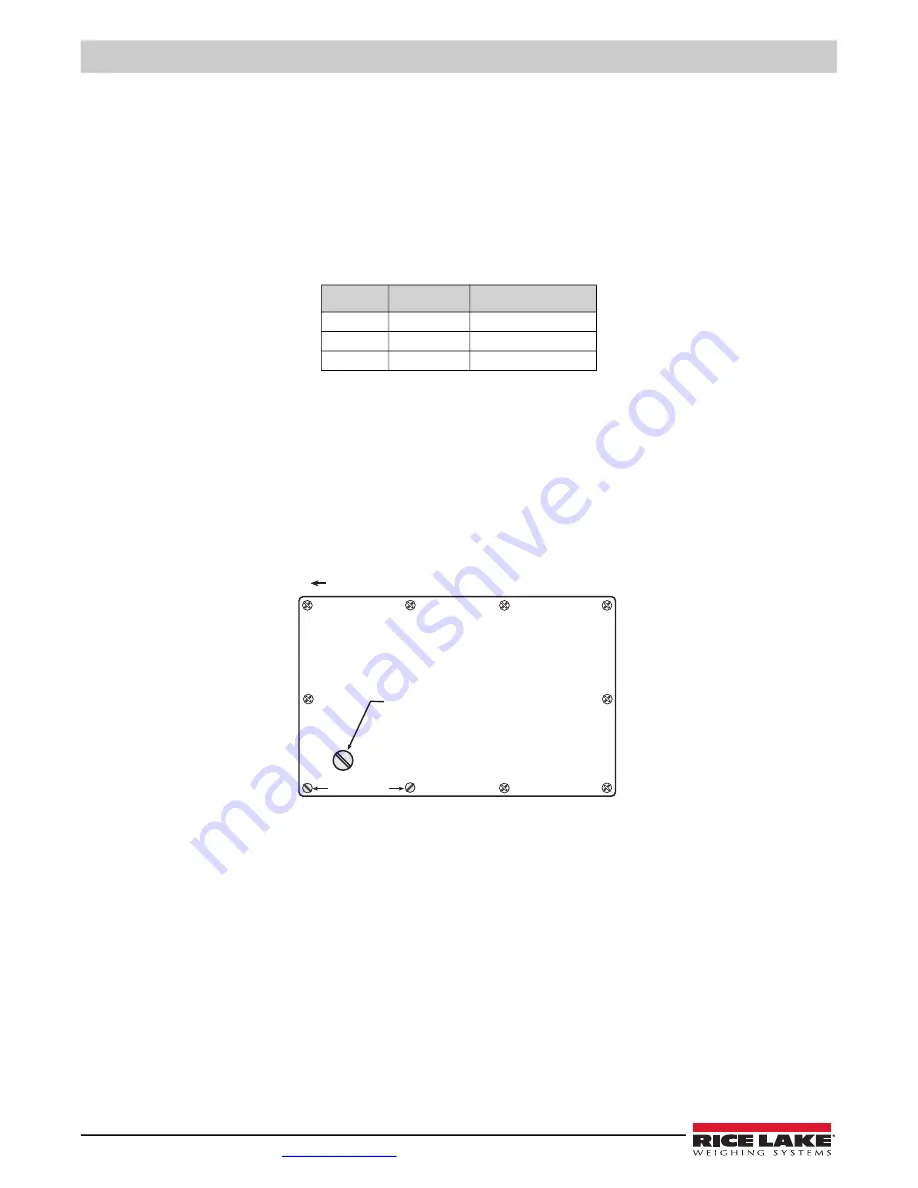

2.3.6 Enclosure Reassembly

Once cabling is complete, position the backplate over the enclosure and reinstall the backplate screws. Use the torque pattern

to prevent distorting the backplate gasket. Torque screws to 15 in-lb (1.7 N-m).

Figure 2-3. IQ plus 210 Enclosure Backplate

2.3.7 Board Removal

If you must remove the

IQ plus 210

CPU board, use the following procedure:

1. Disconnect power to the indicator. Remove backplate as described in

.

2. Remove connections to J5 (load cell cable), J7 (serial communications), J2 and J3 (digital inputs), J4 and J6 (piezo

button inputs), and J1 (setup switch). Remove blue and brown power input wires at J8. See

connector locations.

3. Remove the five nuts from the CPU board, then lift the board out of the enclosure.

To replace the CPU board, reverse the above procedure. Be sure to reinstall cable ties to secure all cables inside the indicator

enclosure.

J7 Pin

Label

Function

1

TxD

RS-232 TxD

2

GND

RS-232 Ground

3

RxD

RS-232 RxD

Table 2-3. J7 Pin Assignments

S e t u p s w i t c h a c c e s s s c r e w

Fillister head screws

10

9

8

7

4

3

1

2

5

6

To r q u e b a c k p l a t e s c r e w s t o 1 5 i n - l b ( 1 . 7 N - m )

To r q u e p a t t e r n

Summary of Contents for IQ plus 210

Page 35: ......