Page 45 / 66

Oil leaks around cylinder

ram or from other points.

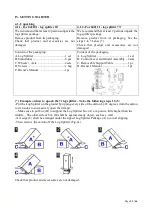

Air sealed in hydraulic system

while operating.

Loosen Bleed Screw by 3~4

rotations before operating the

log splitter

Bleed Screw is not tightened

before moving the log splitter.

Tighten the Bleed Screw up before

moving the log splitter.

Oil Drain Bolt with Dipstick is

not tight.

Tighten the Oil Drain Bolt with

Dipstick.

Hydraulic Control Valve Assembly

and / or seal(s) worn

Contact the dealer

Motor does not start

No current in the socket

Check mains fuse

Electrical extension line defective

Unplug, Check and replace.

Switch or capacitor defective.

Have checked by Electrician

Log Splitter does not

work while motor

running

Valve is not opened owing to the

connection parts loosening

Check and tighten the parts.

Control Levers or Connection parts

bent.

Repair the bent parts

Lower hydraulic oil level

Check and refill hydraulic oil.

6.5- Storage

- Keep the product, the instructions manual and all accessories in the original packaging.

- It is recommended to store the tool in a dry location out of children’s reach.

- Cover the splitter properly if you store it in a shelter or in poorly protected room.

- Protect the motor and especially the switch against water and moisture.

- Do not store anything above or on the splitter

6.6- Disposal

- Do not dispose the product with household garbage. Do not throw into the environment.

- Dispose of the product in a collection centre for waste of electrical and electronic equipment, or a

waste drop-off centre; or seek advice from your local municipality.

- Disposal of the product, accessories and packaging should be carried out according to local

regulations governing environment protection