Page

34

/

60

4.3- Electrical requirements

With a 230V~ 50Hz motor, the log splitter should be connected to standard 230V

10% (50Hz

1Hz).

The electrical supply must be fitted with protection devices of under-voltage, over-voltage, and

over-current as well as a residual current device (RCD), which maximum residual current rated at

0.03A.

Electrical connection rubber cables must comply with EN60245 which are always marked with

H07RN, and with cross section greater than 1.5mm

2

.

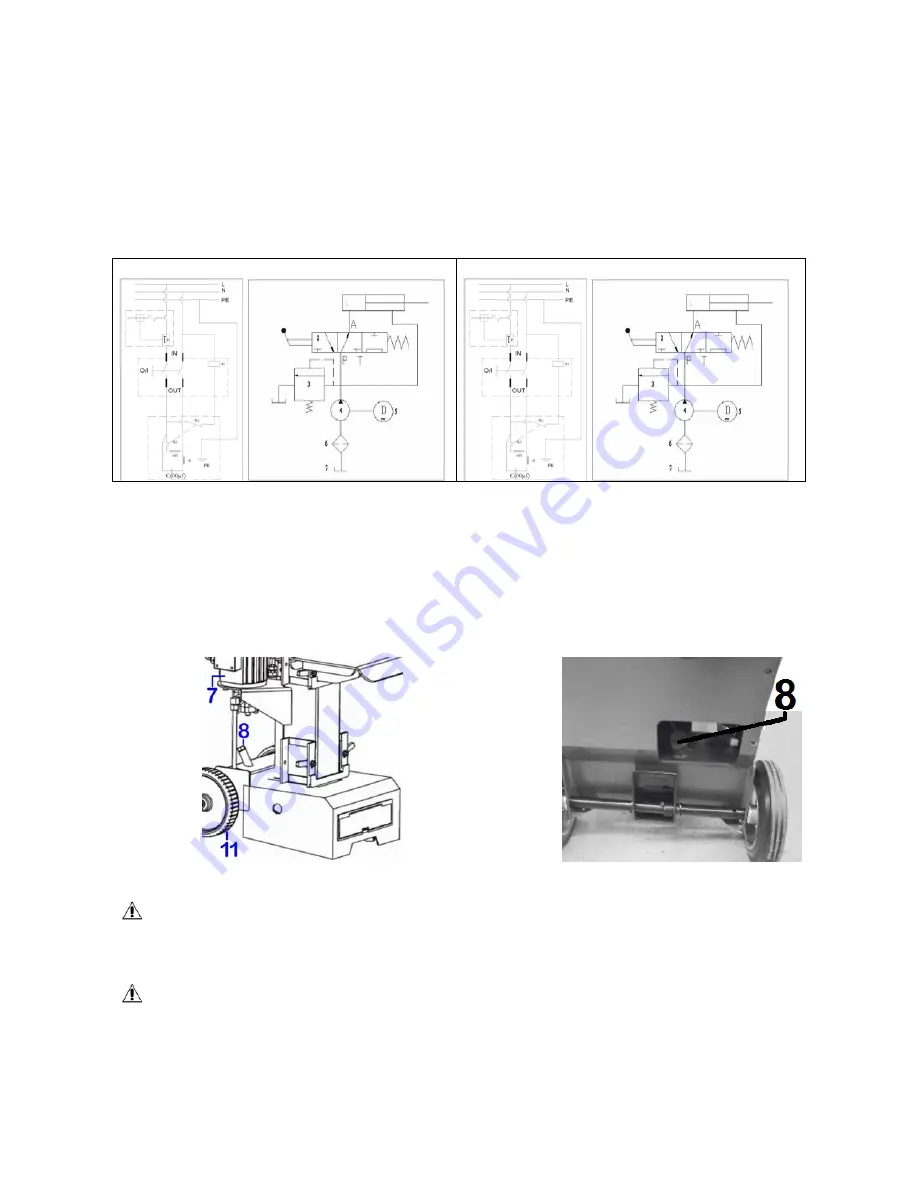

Wiring and Plumbing diagrams

For log splitter 8T PREHLS7T/V / 042091

For log splitter 7T PREHLS71T/VE / 042111

4.4- Bleed the air

Always open the air bleed valve before starting operating the log splitter

4.4.1- For log splitter 8T PREHLS7T/V / 042091

- Loosen the air bleed valve (8 in Fig.15) (oil tank

cover) a few turns whenever the splitter is being used.

- Keep air bleed valve (8) opened during operation.

- Retighten this air bleed valve (8) once you finished.

4.4.2- For log splitter 7T PREHLS71T/VE / 042111

- Loosen the air bleed valve (8 in Fig.16) (oil tank

cover) a few turns whenever the splitter is being used.

- Keep air bleed valve (8) opened during operation.

- Retighten this air bleed valve (8) once you finished.

Fig.15

Fig.16

Failure to loosen the bleed screw will keep the sealed air in the hydraulic system.

The air being compressed and then decompressed, such continuous air compression and

decompression will blow out the seals of the hydraulic system and cause permanent damage to the

log splitter.

Before moving or transporting the log splitter, close the bleed screw to avoid any spillage.