CS-610S+PRO Operation Manual V1.3

Page 10 of 16

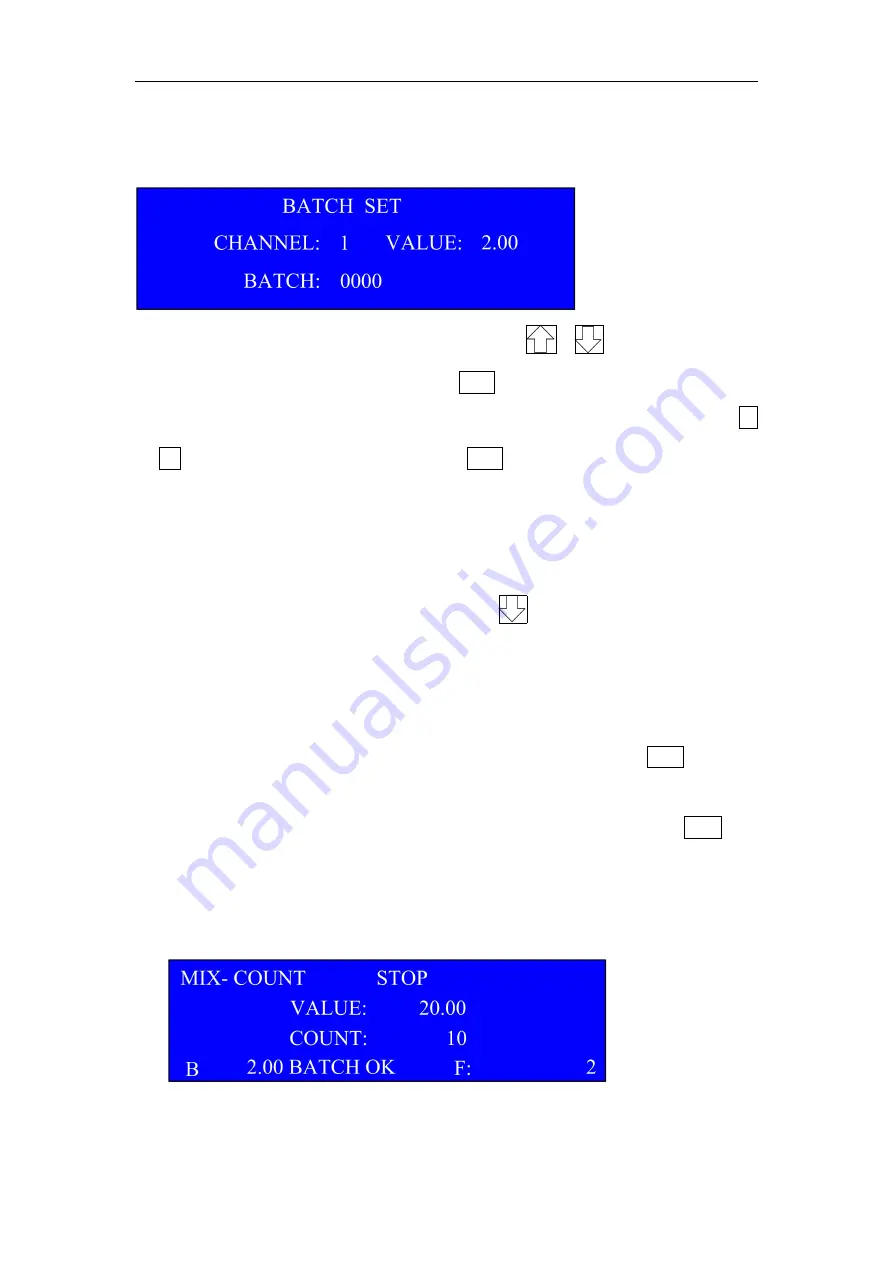

interface:

(1)

BATCH

Enter into BATCH SET interface, press

,

key to switch the

channel. Under one channel, press SET key, the BATCH will flash, at

this moment you can set the BATCH value through the numeric key 0

~ 9

(

the upper limit is 9999

)

.Press CLR key you can clear the BATCH

setting.

NOTES

:

The above steps are used for setting the BATCH number.

If you need to set the BATCH, you need to turn on the BATCH function

in system. Under main interface, press

key to turn on the BATCH

on/off. When BATCH function is on, there is a B shown at the left

corner; if there is no B, it means the BATCH function is turned off.

When one channel Batch No. setting is finished, you can come

back to channel number selection interface by pressing SET key and

then repeat the above number setting way to set batch number for

other target channels. After all settings are finished, press ESC key

to quit from BATCH submenu to come back into main menu interface.

When the machine reaches set Batch number, the LCD display will

show as follows: