adjustment screw (see Figure 16)

counterclockwise until the pump cuts

out. This will be to confirm the pump cut-

out pressure. The pump should stop at

about 80 psi. Once this is confirmed, turn

the pump pressure adjustment screw

clockwise a couple of turns and re-apply

a heat call to start the pump and furnace

running again.

Continue to adjust the pump until the

mid temperature rise has been reached

and at least 100 psi. is reached. Do not

adjust the pump pressure to over 150

psi.

OIL PUMP/ PUMP

BLEEDING

Before furnace operation can begin, the

fuel line and pump must be bled of air.

To do this, run a clear piece of hose with

a special bleed tool attached from the

bleed port on the pump to a bucket or

can (see Figure 23). First, open the

bleed port by turning it counterclockwise.

Next, turn on the furnace by applying a

heat call or 24 AC volts to the “W”

terminal on the burner. The pump will

begin to force the fuel oil and air through

the clear tube. When no more air can be

seen in the tube, turn off the valve by

turning it clockwise. Finally, turn off or

remove the heat call or 24 AC volts from

the “W” terminal.

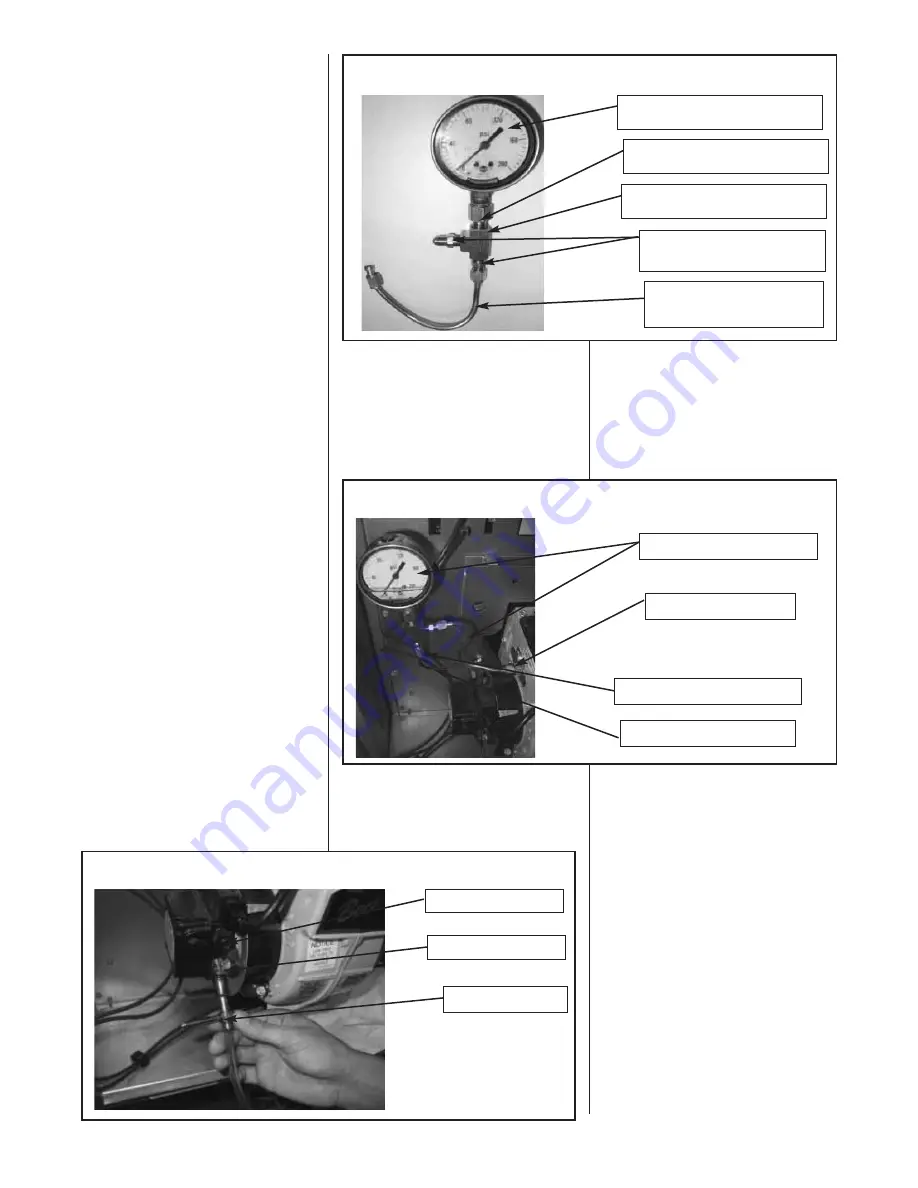

An assembly with a key to open the

bleed port can be constructed like that

shown in Figure 16.

CHECKING THE PUMP PRESSURE

The new Beckett burner assembly now

includes a Clean-Cut shutoff pump. This

pump will prevent oil from dripping into

the heat exchanger after the pump has

stopped. This is an improvement from

the older designs. However, this now

means that the new pump no longer has

a spare port from which oil pressure can

be easily taken.

To check the oil pressure on the new

Clean-Cut pumps, an assembly of tube,

pipe fittings and a pressure gage will

need to be constructed as shown in

Figure 17. The figure shows a list of

components necessary to create the

assembly. Other assemblies can be

made, as this is not the only assembly

that will work. This assembly can be

used to check the pressure on other -

OPF and -OBF oil furnaces so that only

one assembly is necessary for a toolbox

used in the field. Construct the assembly

as shown in Figure 17 and install it as

shown in Figure 18.

Once the pressure testing assembly has

been made and installed as shown in

Figure 18, turn on the furnace by

applying a heat call or applying 24 AC

Volts to the “W” terminal on the

thermostat input terminal block. After the

burner starts and flame has been

established, turn the pump pressure

Once the pump pressure has been

properly adjusted, remove the pump

pressure reading assembly and replace

the fittings and tubes to their original

configurations. Next, repeat the bleeding

procedure as above to insure that no air

remains in the oil supply line.

PUMP SELECTION

For all -OBF and -OPF oil furnaces that

use the R7184 primary control, a Clean-

Cut pump with solenoid must be used.

Use of a standard pump without the

necessary solenoid will prevent

operation of the furnace. For this reason,

pumps from -OPC, -OPD, -OBC and -

OBD oil furnaces cannot be

interchanged with or used on the -OBF

or -OPF models.

For long pipe runs and installations

where the oil tank is below the burner, a

separate two-stage pump is available

from the parts replacement division. Be

sure to purchase a two-stage pump with

Clean-Cut solenoid. Use of a pump

without a Clean-Cut solenoid will prevent

furnace operation.

For information on when to use a two-

stage pump, consult the section titled

“OIL BURNER / PRIMARY CONTROL”

of this document.

FIGURE 17

EXAMPLE OF OIL PRESSURE TESTING ASSEMBLY.

16

General Service Pressure Gage 0-200 psi

Range with 1/4” NPT Male Connection

Brass Threaded Pipe Adapter Fitting –

1/4” NPT Male to 1/8” NPT Female

Brass Threaded Pipe Fitting – Tee with

1/8” NPT Female Thread

Compression Tube Fittings – Male

Straight Adapter (Self Aligning)

3/16” OD Tubing to 1/8” NPT Pipe

3/16” Copper Tubing with Standard

3/16” Compresion Tube Fittings on

Both Ends Approx. 4” Long.

FIGURE 18

OIL PRESSURE TESTING ASSEMBLY INSTALLED

FIGURE 16

BLEEDING THE PUMP

Pump Pressure Adjustment

Pump Bleed Access Port

Bleed Tool with Hose

Attached

Oil Pressure Testing Assembly from

Figure 17.

Install Oil Pressure Testing Assembly

to Existing Tube as Shown.

One Fitting to Mount to Burner

Existing Tubing Provided on Burner