PRE-HOISTING CHECKLIST

This checklist must be checked prior to each use of the Handihoist. This checklist is to be used as a guideline in

conjunction with the maintenance and inspection procedures outlined in this manual. The Handihoist and related

equipment must be thoroughly inspected prior to each use by a trained person. A trained person is one who has read and

thoroughly understands this instruction manual and related equipment manuals and, through training and experience, has

shown knowledge regarding the safe operational procedures. If you do not have such a person in your organization, please

contact Reimann & Georger Corporation or its distributors and they will assist you in providing such a “trained person.”

Do not permit any person who is not fully trained to operate this Handihoist. It is recommended that this checklist be

maintained as a permanent record.

Discuss work plan, personal protective equipment, and each crew member’s responsibility before starting to set-up.

Ensure OSHA compliant fall protection is in place.

Ensure hoisting operation will clear all power lines and obstructions.

Ensure hoisting area is secured from all unauthorized personnel.

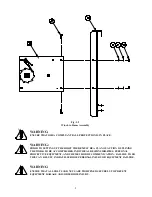

Ensure the track is securely tied to the roof to prevent track from slipping.

Ensure that both track shoes are resting on a firm level surface

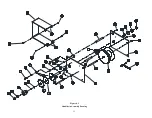

Ensure the load does not exceed the rated load capacity of the hoist model being used.

Ensure all structural members of the Handihoist are free of defects and damage that may affect the integrity of the

Handihoist.

Inspect wire rope for signs of wear and damage. Replace defective wire rope immediately.

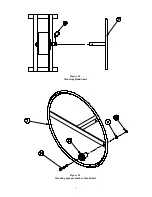

Ensure that at least three wraps of wire rope are on the winch drum at maximum travel.

Ensure that the screw securing wire rope end loop to the brake sheave is tight and in good condition.

Ensure wire rope is reeved properly for either one (1) part of line for the Handihoist 200 hoist or two (2) parts of line

for the Handihoist 400 hoist.

Ensure that track support has been properly installed for track lengths over 28 feet.

Ensure that the bottom of the track is away from the building 1/4 of the supported height plus the building overhang.

Ensure that all bolts and nuts are tightened securely.

Ensure all sheaves can rotate freely.

Ensure safety latch on the hook does not support any load.

Ensure Handihoist has been properly maintained.

Operate hoist with no load to test hoisting operation

INSPECTOR: _____________________________________ DATE: ______________