16

Installation

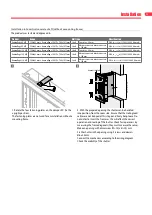

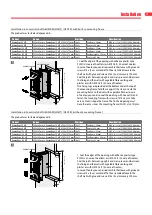

Installation into vertical shaft PROMATECT L500 with built-in mounting frame

The product was tested and approved in:

Product

Range

Wall type

Classification

Kamouflage 60 MP

350x385 mm ≤ Kamouflage 1V MP ≤ 700x1075 mm Shaft

Promatect L500 ≥ 30 mm EI 60 (v

ed

i

n

o) S 1500 C10000 AA multi

Kamouflage 120 MP

350x385 mm ≤ Kamouflage 1V MP ≤ 700x1075 mm Shaft

Promatect L500 ≥ 40 mm EI 90 (v

ed

i

n

o) S 1500 C10000 AA multi

Kamouflage 120 MP

350x385 mm ≤ Kamouflage 1V MP ≤ 700x1075 mm Shaft

Promatect L500 ≥ 50 mm EI 120 (v

ed

i

n

o) S 1500 C10000 AA multi

e

≥ 125 mm

KAMOUFLAGE MP

EASY-KAP ME/MP

e

A = 2 x e + 20 mm

(W+

A

) x (H+

A

) mm

(W+

20) x (H+

20) mm

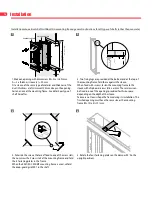

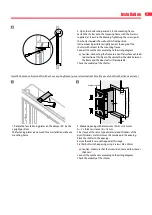

1. Assemble the sleeve with staples and affix the assembled

sleeve to the shaft wall with staples.

Coat the edges of the opening with adhesive plaster type

Promacol S.

Screw the mounting frame to the sleeve with chipboard screw

(Ø 6 x e)mm. Two fixing lugs are provided at the bottom and at

the top of the mounting frame: fold these against the sleeve.

Seal the mounting frame with Promacol S taking care not to

misshape it. The finished opening must have the same size as

the mounting frame (W+10) x (H+10) mm.

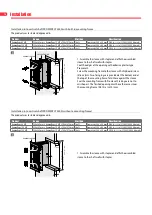

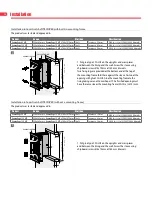

Installation into vertical shaft PROMATECT L500 (without a mounting frame)

The product was tested and approved in:

Product

Range

Wall type

Classification

Kamouflage 60 MP

350x385 mm ≤ Kamouflage 1V MP ≤ 700x1075 mm Shaft

Promatect L500 ≥ 30 mm EI 60 (v

ed

i

n

o) S 1500 C10000 AA multi

Kamouflage 120 MP

350x385 mm ≤ Kamouflage 1V MP ≤ 700x1075 mm Shaft

Promatect L500 ≥ 40 mm EI 90 (v

ed

i

n

o) S 1500 C10000 AA multi

Kamouflage 120 MP

350x385 mm ≤ Kamouflage 1V MP ≤ 700x1075 mm Shaft

Promatect L500 ≥ 50 mm EI 120 (v

ed

i

n

o) S 1500 C10000 AA multi

KAMOUFLAGE MP

e

≥ 125 mm

e

A = 2 x e + 10 mm

(W+

A

) x (H+

A

) mm

(W+10) x (H+10) mm

1. Assemble the sleeve with staples and affix the assembled

sleeve to the shaft wall with staples.

1

1