61

SSCBL-RPBL-IOM (10-22) 149159-C

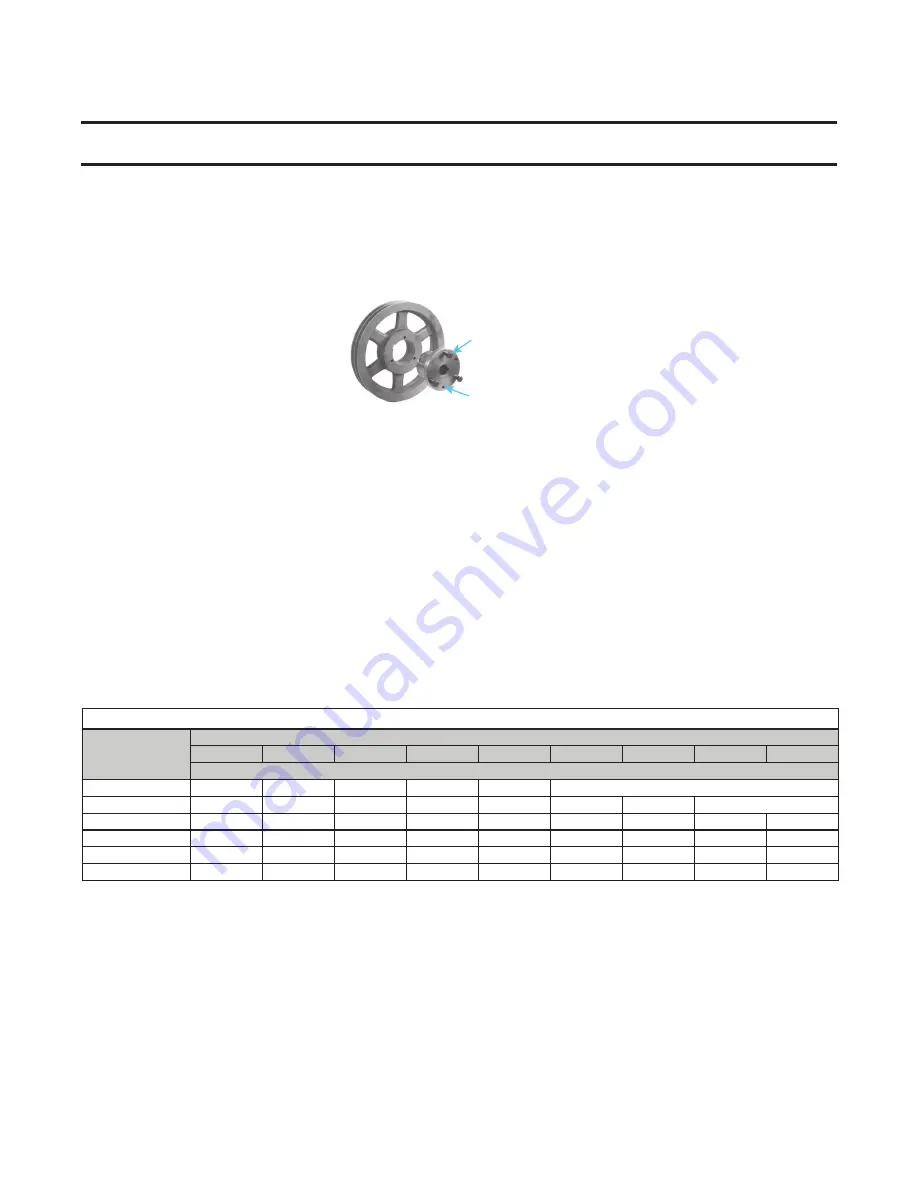

Figure 44. Split Taper Bushing

Reversing Blower Rotation

Each blower housing is marked for proper rotation . Rotation may be changed on single-phase motors by rewiring in

the motor terminal box . Rotation may be changed on three-phase motors by interchanging two wires on the three-

phase supply connections .

Motor Load and Amp Adjustment

•

Amps may be adjusted downward by reducing blower RPM or by increasing duct system static pressure . Use an

ammeter to check blower motor amps .

•

See the motor rating plate for exact motor specifications . Do not exceed the amp rating on the motor nameplate .

•

Venter motor amps for a 115V or 575V unit = 1 .5A . Venter motor amps for a 208V, 230V, or 460V unit = 0 .8A .

•

, which lists the Full Load Amps (FLA) of blower motors (open) based on Horsepower (HP) and Voltage

(V), can be used for sizing line wiring but should not be interpreted as the exact motor amps .

CAPSCREW

PUSH-OFF HOLE

Table 30. FLA of Blower Motors (Open, Single-Speed, Average Values)

Voltage/Phase

HP

1

1-1/2

2

3

5

7-1/2

10

15

20

FLA

208V/1PH

7 .2

10 .1

11 .3

13 .7

28 .0

—

230V/1PH

6 .5

9 .1

10 .2

12 .4

26 .0

32 .0

38 .0

—

208V/3PH

3 .6

5 .8

7 .3

9 .3

14 .6

23 .2

28 .8

42 .0

55 .3

230V/3PH

3 .2

5 .2

6 .6

8 .4

13 .2

21 .0

26 .0

38 .0

50 .0

460V/3PH

1 .6

2 .6

3 .3

4 .2

6 .6

10 .5

13 .0

19 .0

25 .0

575V/3PH

1 .3

2 .1

2 .6

3 .4

5 .3

8 .4

10 .4

15 .2

20 .0

•

At final adjustment, amperes should not exceed motor nameplate amp rating . The installation must be adjusted

to obtain a temperature rise within the range specified on the furnace rating plate .

NOTE: Some blower pulleys require the use of a split taper bushing in the blower pulley. These

split taper bushings must be loosened in order to remove the pulley.

•

If it is necessay to remove a blower pulley, follow these instructions to loosen the bushing:

) . Remove three capscrews .

b . Insert two capscrews into two push-off holes and tighten evenly until pulley is loosened .

c . Pulley may now be removed from shaft .