7

CP-CAUA-GC (04-21) 170635-A

c. Recheck all manifold connections for gas leaks in accordance with step 5.

7. Measure and adjust manifold (outlet) pressure:

⚠ WARNING ⚠

Manifold gas pressure must never exceed 3.5 IN WC for natural gas or 10 IN WC for propane.

Incorrect inlet pressure could cause excessive manifold gas pressure.

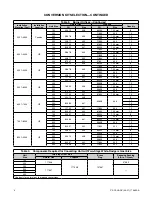

a. Ensure that inlet (supply) pressure is in accordance with

and determine correct manifold (outlet)

pressure (refer to

).

Table 5. Gas Pressure Requirements

Natural Gas

Propane

Minimum

Maximum

Minimum

Maximum

Inlet (Supply) Pressure (IN WC)

5.0

*

14.0

11.0

*

14.0

Single-Stage and Two-Stage High-Fire

Two-Stage Low-Fire

Natural Gas

Propane

Natural Gas

Propane

Manifold (Outlet) Pressure (IN WC)

3.5

10.0

1.8

5.0

*

Or as stated on the unit rating plate.

b. Turn knob or switch on top of valve to OFF to prevent flow to gas valve.

NOTE: A manometer (fluid-filled gauge) is recommended rather than a spring-type gauge due to

the difficulty of maintaining the calibration of a spring-type gauge. Use a water column manometer

that is readable to the nearest tenth of an inch.

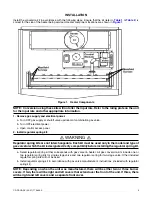

c. Connect manometer to 1/8-inch output pressure tap on valve (see

).

SINGLE-STAGE VALVES

TWO-STAGE VALVE

REGULATOR

SCREW

INLET

PRESSURE

TAP

1/8" OUTLET

PRESSURE

TAP

1/8" OUTLET

PRESSURE

TAP

INLET

PRESSURE

TAP

REGULATOR

SCREW

INLET PRESSURE TAP

1/8" OUTLET PRESSURE TAP

HIGH-FIRE

REGULATOR SCREW

LOW-FIRE

REGULATOR SCREW

Figure 2. Gas Valves